Salmon by-product used to make greener cleaners

Scottish start-up Eco Clean Team is undertaking a research project with experts from the University of St Andrews to develop a new process that uses by-products from fish farming to produce surfactants – one of the main components in detergents and other industrial and institutional cleaning products.

With six-figure funding support from the Industrial Biotechnology Innovation Centre (IBioIC), Eco Clean is aiming to develop a more sustainable alternative to traditionally petrochemical-based surfactants, which can be produced at scale.

Surfactants – or surface active agents – are used in detergents to disrupt the surface tension on the item being cleaned, helping to trap and remove dirt. Different types of surfactants are used as wetting agents, emulsifiers, and foaming agents for a range of products.

Valuable compounds

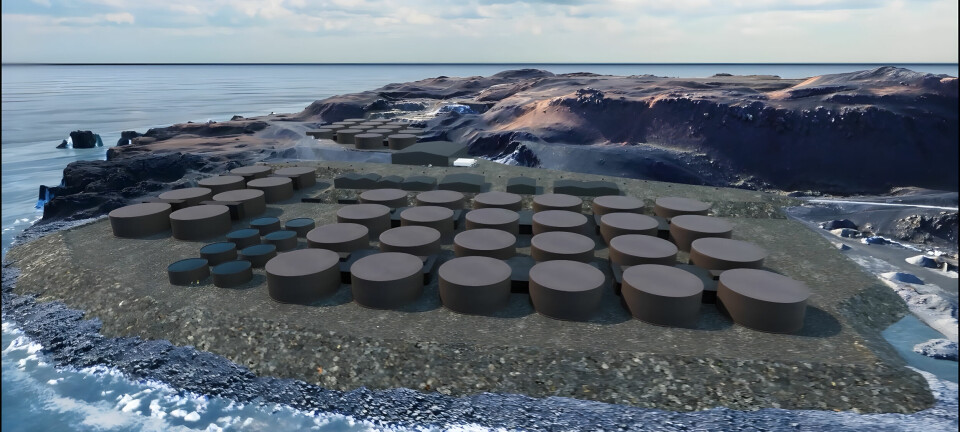

Eco Clean’s circular approach uses waste from the growing Scottish salmon sector to create the valuable chemical compounds, focusing especially on the fish oils rich in fatty acids which account for around a quarter of the sector’s total by-product output. Last year, the sector produced more than 200,000 tonnes (live weight) of Atlantic salmon.

Salmon farmers have been taking steps to reduce and reuse by-products for several years, with a recent example being the formulation of biodiesel. However, this project could unlock an opportunity to create higher-value sustainable products with a long-term application.

The bio-based process developed by researchers at the University of St Andrews is more cost effective, efficient and eco-friendly than traditional methods of producing surfactants. The next stage of its development will ensure the new method is replicable, straightforward to implement, and allows surfactants to be produced in high volumes.

‘A critical step’

Mark Hamilton, co-founder and director at Eco Clean, said: “While working on a project for the development of a new cleaning product, I began to look at how one of the core ingredients could be produced in a more sustainable way. This developed into the project Eco Clean is working on today.

“This next stage in our research represents a critical step in the process of development then scaling up the production of our sustainable surfactant. We have already proved the feasibility in a previous study and hope that, by the end of this project, we will find ourselves closer to full-scale commercialisation and seeing the surfactant used in a range of industrial and selected household products.

“I was born and grew up in Tarbert, Loch Fyne, so aquaculture and fishing are close to home for me, and I have seen first-hand the importance of both to communities in Scotland. However, as the sector grows it needs to do so sustainably, and we believe this project is just one example of a new valuable solution that can come from its by-products.”

Scaling up

The project builds on the success of a feasibility study which was jointly funded by IBioIC and the Sustainable Aquaculture Innovation Centre (SAIC) in 2020, with the team having secured funding to take the concept to the next stage of scaling up.

Dr Alfredo Damiano Bonaccorso, senior research fellow at the University of St Andrews, said: “This project with Eco Clean is an excellent case study of how research can help a novel company to develop an idea by transferring insight and knowledge from academia to industry.

“The first time I met Mark, he was full of enthusiasm for the idea, keen to develop a sustainable method for producing cleaning products. I was already using fish oil waste to produce biofuel, so decided to explore a similar process and feedstock to produce a bio-based surfactant and we were pleased to see success from the initial feasibility study.”

Sustainability targets

Liz Fletcher, director of business engagement at IBioIC, added: “Bio-based alternatives to petrochemicals will be an essential part of meeting global sustainability targets, and there are wide ranging opportunities to use natural feedstocks that one industry might consider by-products as the building blocks for new products and chemicals. Eco Clean is a great example of a Scottish company helping to grow our bioeconomy by seizing the opportunities biotechnology presents to create more sustainable products.”