Foreign buyers eye Machrihanish RAS plant

An experimental recirculating aquaculture system (RAS) salmon farm at Machrihanish has attracted interest from potential buyers in Norway, the United States and Thailand.

Norway-based owner Niri announced earlier this month that having developed the farm in an aircraft hangar at the former airbase on the Kintyre peninsula to prove Niri’s RAS technology, the company’s shareholders had decided to offer the facility for sale.

Gordon Boyle, managing director of Niri subsidiary, Niri Scotland Ltd, said the intention was to find a partner who could take advantage of Niri’s technology and expertise to develop a commercial-scale RAS salmon farm on the site and was prepared to fund the scale-up.

“None of Niri’s shareholders are fish farmers, they are involved in many different activities in the fish industry, but they would certainly see themselves as not expert in the commercial side of fish farming,” said Boyle.

“They now need to find a partner who would be willing to come in and invest in that facility. From Niri’s perspective, the plan would be the next stage in the Niri story, where the development of Machrihanish would use the Niri technology.”

Boyle added: “I personally met with a company based out of Thailand, one of my fellow directors at Niri Scotland is dealing with a guy who has a fish farming operation in America, and I know that back in Norway Niri has been approached directly over there. But nothing has yet been progressed to sell it to any individual or company.”

Room for millions of fish

Boyle said there was plenty of room for expansion at Machrihanish. “The tank they have in the hangar can hold over 20,000 fully grown 4.5-5 kilo fish, and I would estimate you could have 12 of that size of tank inside the hangar, no problem at all,” he said.

“In addition to that they have 60 acres of land around the hangar, so you could have dozens of tanks, and therefore produce millions of fish, if you wanted to.”

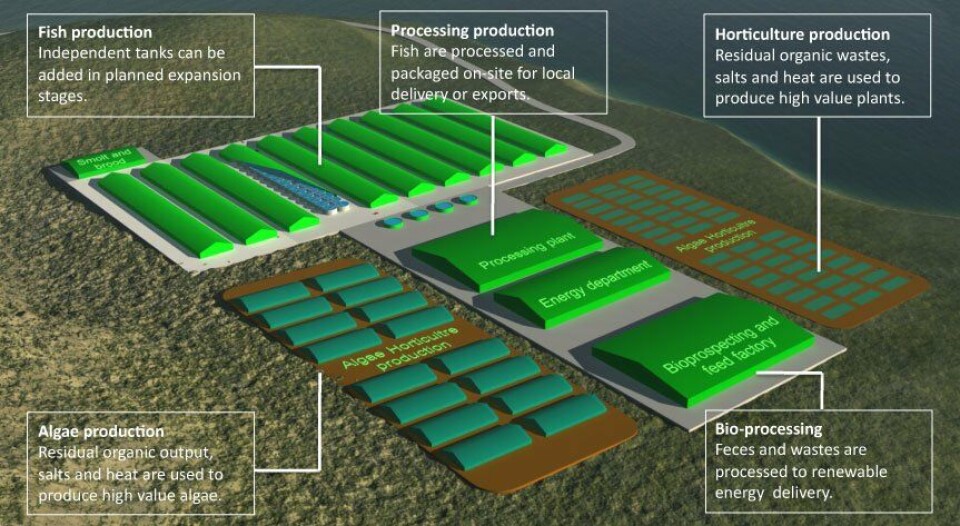

Niri’s system is based on independent production units, each of which is a large rearing tank with fully integrated recirculation and filtration technology, allowing investors to build the business tank by tank without the large upfront capital expenditure required for a facility with a centralised RAS, he added.

Successfully grown to market size

Niri’s experiment to grow 26,000 Atlantic salmon at Machrihanish was run by Niri founder and former managing director, Arve Gravdal, who is no longer with the company. In November last year Gravdal told fishfarmingexpert.com that the fish had been successfully grown to market size, but a decision had been taken not to sell them to market because they had been contaminated with detergent after a problem with the water supply.

However, Niri’s chairman, Trond-Inge Kvernevik, said the company had decided to slaughter and compost the fish because they had served their purpose by proving they could be successfully grown and had outlived their usefulness.

“The results coming out of it could not defend the costs we were having,” said Kvernevik, who joined the company along with a new board of directors at the turn of the year in 2017.

“We wanted to benchmark certain production targets, certain documentation out of that batch of fish, and from my perspective I see that the history of the project, also before the new board came in, was that there were certain operational challenges.

'Project was under-funded'

“I would say that the project was under-funded, the funding was intermittent, which didn’t give a very easy management situation on site. Some incidents occurred, early in the project, with some stress on the fish.

"We have learnt about some installation problems, which were really trivial mistakes and never had to happen, with faulty installation of sensors that caused problems with the pH values and so forth. We’ve also had reports that there were incidents of overfeeding, probably with creation of some hydrogen sulphide in the system. I will not put my finger on any specific factor but in view of all the variation we’ve learnt about in the project, it would have been unwise to keep up the costs when the benchmarks we got out would not be worth that further investment in that particular batch of fish.

“Above all it has been an extremely useful phase for Niri that has allowed us to upgrade our technology to an industrial standard and prepare the company to take on the market as a competitive supplier for land-based farming of both post-smolt and harvest size salmon.

Active participant

“I have heard about pollution in the water but in that case the supplier of the water would have a liability, so we looked in that issue, and have not been able to get any documentation of pollution in the water.”

Kvernevik said it was Niri’s intention to be an “active participant” in building up any project at Machrihanish, providing not just technology but also knowhow and a network of competent, qualified people. In 2017 Niri recruited personnel with extensive RAS operating experience and intensified cooperation with RAS-engineering companies, to bring its concept for industrial fish farming to the market.

“When you run a RAS at high intensity, if something technically goes wrong, you only have 10 or 15 minutes to respond to avoid mortality, so it’s a very critical operation where you have to have excellent operators, excellent monitoring and smooth operations,” said Kvernevik.