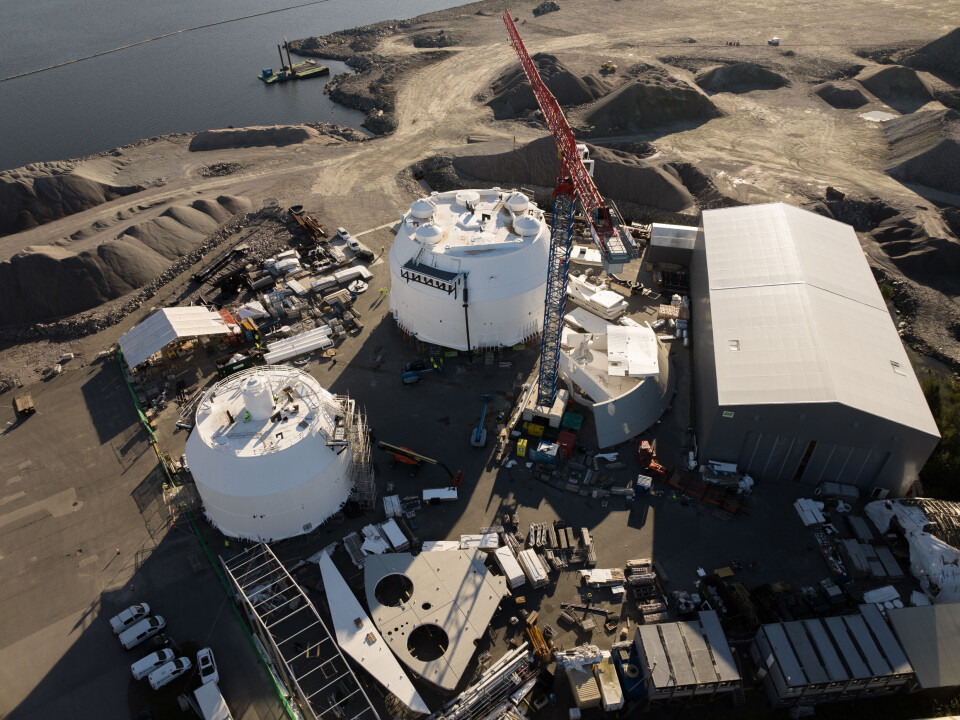

FishGlobes get readied for the Red Sea

Contractor Bluegreen has successfully launched two autonomous floating closed fish farms that are now heading towards the testing phase and then a customer in Saudi Arabia.

Two “FishGlobe” floating closed containment units have been put into the water in Norway ahead of their export to Saudi Arabia later this year.

The units, made from polyethylene (PE), have internal volumes of 3,500 cubic metres and 10,000m³ respectively, and have capacities for 262 tonnes and 750 tonnes of fish.

The larger unit was towed out of Norway’s Frierfjord on Wednesday evening and the smaller unit was towed out yesterday. Both are being transported from Frier Vest in Telemark county, southeast Norway to Arendal, about 60 miles to the southwest, for inspection, testing and completion.

They will then be transported by ship to the Red Sea, where they will be used for farming a species of seriola (amberjack) as part of Saudi Arabia’s Neom project in the northwest of the kingdom.

Logistical challenge

The FishGlobes are supplied by the company Fishglobe Technologies, and built from PE panels made and assembled by Bluegreen, which also makes its own PE floating closed containment system, the Marine Donut.

Transporting the FishGlobes from Bluegreen’s construction yard to the launch site on the Frierfjord was a complex operation, even though it covered a distance mof just a few hundred metres. Each unit was moved by hydraulic trolley systems across Frier Vest, where thew port authority is building a new “smary quay”, and out to the quay where a crane with an 800-tonne lifting capacity was anchored.

The units were then lifted and lowered into the water for towing.

Proud of the team

“Moving such enormous units over land, across docks and into the water – with precision and control – is demanding, but the team delivered at a very high level. We are proud of everyone involved,” said Bluegreen sales and marketing director Geir Andresen.

The FishGlobes are developed to provide improved biosecurity, reduced sea lice and efficient sludge management, and can be used for both post-smolt and food fish production.

With the yard cleared of the two globes, Bluegreen is starting construction of a new FishGlobe – a massive 30,000m³ unit that is due go to Norwegian salmon farmer Nova Sea next summer.

“Strictly speaking, the work is already under way. We have been producing panels for a long time, and now that the ‘small’ globes have left the shipyard, we have space to begin assembly,” said Andresen.

Fishglobe Technologies believes Norway will be its main market in the long term, but the order in the Middle East is being used as a springboard.

“If we open that market, we believe that we can take a significant market share in a segment with increasing need for our type of technology,” said chief executive Tor Magne Madsen.

One of the company's most important advantages is its Salmatic remote control system.

24/7 operations centre

“First and foremost, this distinguishes us from competitors who have less technology integration. We are building a 24/7 operations centre that will monitor the technology and provide customers with security,” explained Madsen.

“From next year, we will have operations on several continents connected to the centre.”

Through the system, the company can monitor the operation of several plants simultaneously, and connect everything from sludge treatment plants to land-based units.

'One globe per month'

“Having produced 20 generations, it gives us a transfer of experience that customers benefit from. Our goal is to create security for the technology, while the farmers can concentrate on growing the fish.”

Fishglobe Technologies has targeted a turnover of NOK 1 billion (£75 million at today’s prices) in 2030.

“To achieve this, we will develop and standardise the product to be able to deliver one globe a month,” said Madsen.