A concrete case for floating closed containment

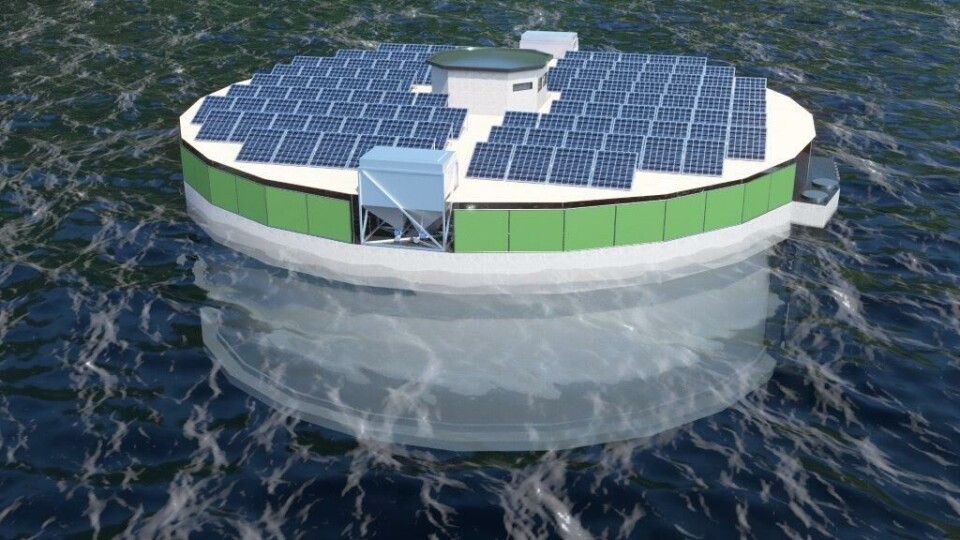

Two veteran fish farming entrepreneurs have unveiled plans for a floating concrete fish cage which would offer a large increase in scale on for concrete systems.

Knut Solberg and Bjørn Myrseth have designed the Futurum Basin, based on experience from the Stadium Basin, another floating structure now being developed by Norwegian salmon farmer Lingalaks and pump maker Framo.

Solberg was in the initiator of the Stadium Basin project, and Myrseth is a biologist and businessman who was a co-founder and former chief executive of on-land turbot and sole producer Stolt Sea Farm, among other things.

Cloth and composite

He points out that Norway has a long history of producing fish in closed fish farms at sea. The first to come into operation was in 1985 when Marenor AS started farming salmon at Slemmestad in the Oslo Fjord.

“The bags were made of cloth. This has been the material that has been used in almost all previous attempts to fish in closed facilities,” says Myrseth.

“Later we got farms in composite material and several types used bags of plastic cloth. Only one small plant has previously been built in concrete, and then with a volume of 1,000m³. The Futurum pool of 15,000m³ represents a big jump upwards.”

Long service life

Concrete structures are strong and have a long service life even in the sea when built correctly with high quality material.

“The service life will then be over 50 years. The concrete structures in the platforms in the North Sea have an estimated service life of about 100 years, but experience and measurements show that they can probably be used for a significantly longer period of time. Concrete will also be maintenance-free,” says Myrseth.

The two men drew on their experience of farming in large RAS facilities to calculate water exchange and fish density.

Flow analyses

“The plan is to be able to have a density of up to 50 kg per m³ with a water exchange time of 30 minutes. Computerised Flow Dynamics (CFD) analyses have been used to obtain optimal water flow and good collection of sludge,” says Myrseth.

The design is further based on construction with elements that are cast together.

“This provides simple and affordable construction compared to the use of formwork. The use of special concrete makes the plant a little lighter than if it had been built with standard concrete.”

No lice issues

Myrseth believes there are many well-documented benefits of farming in closed facilities.

There are no problems with lice, so damage caused by lice, or by the work of removing lice, is eliminated.

There is a low risk of algae problem. The sludge can be collected and escape is unlikely. All this is has been thought about when designing the pool, which is designed with walls to prevent lice from entering from wave splashes.

Renewables on board

Closed facilities need energy for operation of pumps, and this can come from the generator on board or from shore power.

“For the Futurum pool, we’re also working with the installation of solar cells and perhaps also a wind turbine. Preliminary calculations show that a large part of the energy needs can be covered by renewable energy produced on board,” he says.

Other benefits he highlights with a large concrete pool are that there is room for storage of feed, mortalities and sludge on board in a large centre pillar.

“A big advantage of the Futurum pool is that it is easy to empty the pool completely of fish and water and to clean and disinfect the walls before exposed by new fish.”

Firmer meat

It has been shown that fish swim more in closed facilities than in open cages, says Myrseth, which is believed to give a stronger smolt and harvest-sized fish with firmer meat.

“It is possible to taste the difference,” Myrseth claims.

The Futurum pool can be used both to grow harvest-sized fish and for the production of large smolts.

“The Futurum pool will be a truly green facility that will provide environmentally friendly farming. All experience and calculations show that without lice treatment the total cost of farming in Futurum pool will be no higher than current costs in open cages,” concludes Myrseth.