Lobster farmer claws back energy used by data centre

A Norwegian lobster growing pioneer is to build an on-land farm beside a large data centre to take advantage of warm water from the centre’s cooling process.

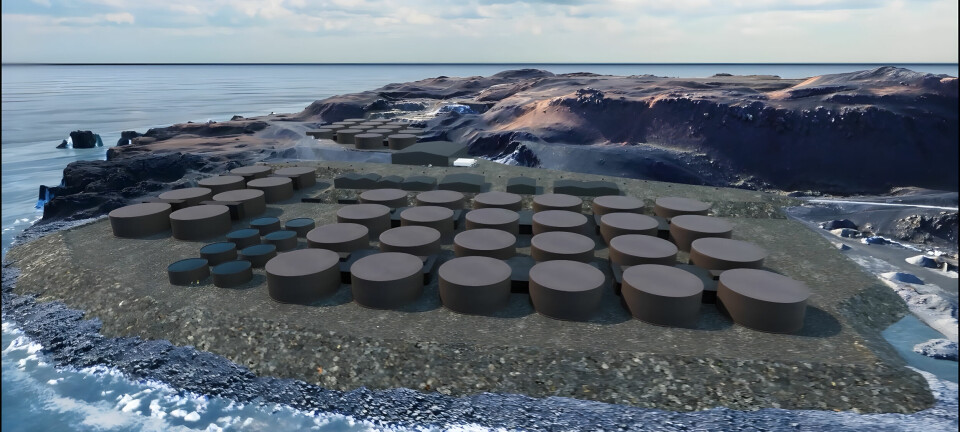

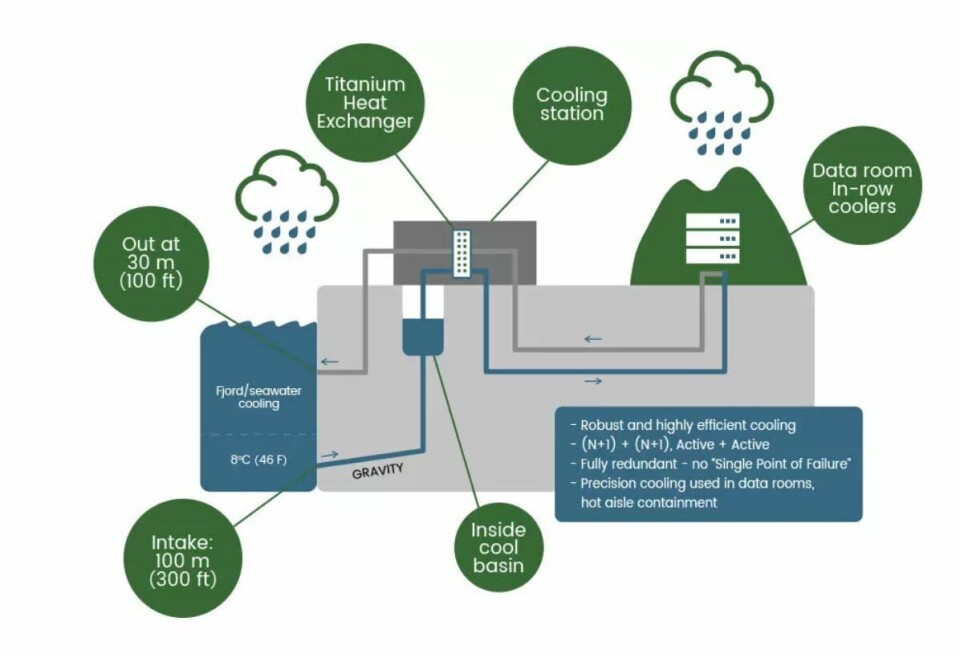

The Green Mountain data centre on the island of Rennesøy, near Stavanger, draws water from the depths of a fjord to cool the computer servers in the facility.

The water enters with a temperature of 8° C and is released back into the fjord with a temperature of 20° C, the optimal temperature for lobster growth.

Highly cannibalistic

Green Mountain has entered into a cooperation agreement with Norwegian Lobster Farm to use the cooling water in a new farm which will have a significantly reduced environmental footprint, the companies said in a press release.

Norwegian Lobster Farm says demand for lobsters far outstrips supply and claims current aquaculture methods are commercially unviable as lobsters are highly cannibalistic and cannot be reared in groups, making aquaculture unscalable and inefficient.

The company has developed the first-ever land-based recirculating aquaculture system (RAS) solution for producing high-quality European lobsters (Homarus gammarus) at commercial scale, using individual cages to prevent cannibalism, and automation / robotics to lower production costs, ensuring a high degree of profitability.

No need for a RAS

Building a farm that uses Green Mountain’s cooling water means the heat energy from the computer servers is re-used and there is no need for an expensive and complicated RAS.

“In practice, this means that we can scale up production with reduced technical risk, as well as save both investment and operating costs. In addition to the environmental benefits, of course,” said Norwegian Lobster Farm chief executive Asbjørn Drengstig in a press release.

The company has spent several years on research and development and has benefited from EU funding through the Horizon 2020 and EuroStars programmes. It envisages being able to start construction of the production facility this year.

The company’s portion lobsters are 20 cm long and weigh about 250 grams. The lobsters have not undergone sexual maturation, which means that the product maintains a very high quality.

Fits like a glove

Green Mountain chief executive Tor Kristian Gyland said: “We have been working for a long time with various methods to reuse the residual heat from our data centre.

“Here on Rennesøy, where there is a long distance between the homes, for example, district heating is not a sensible alternative. This project, on the other hand, fits like a glove. We hope we can also expand this and similar concepts to our future facilities.”

Green Mountain has data centres at Rennesøy, in Telemark and near Olso. All use renewable electricity.