FlexiFarm promises fewer losses, lower costs

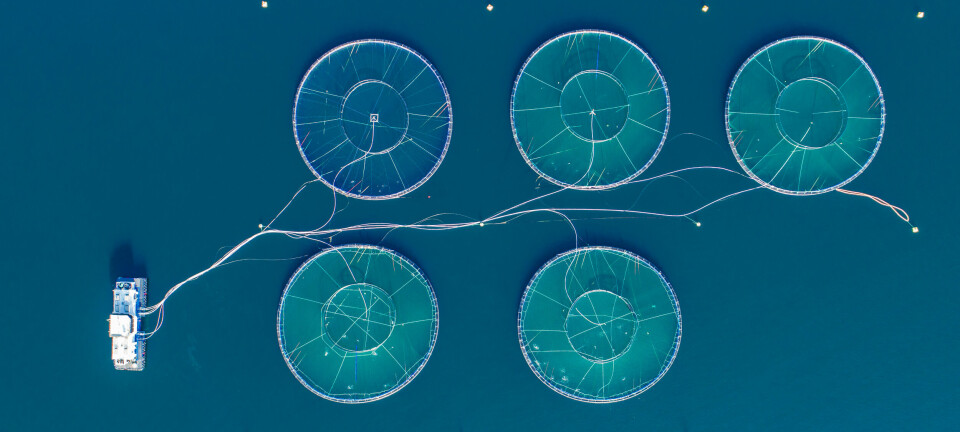

Global salmon farmer Cermaq has unveiled plans for a closed containment system based on flow-through technology that it claims takes closed containment to a new level, while at the same time reducing production costs.

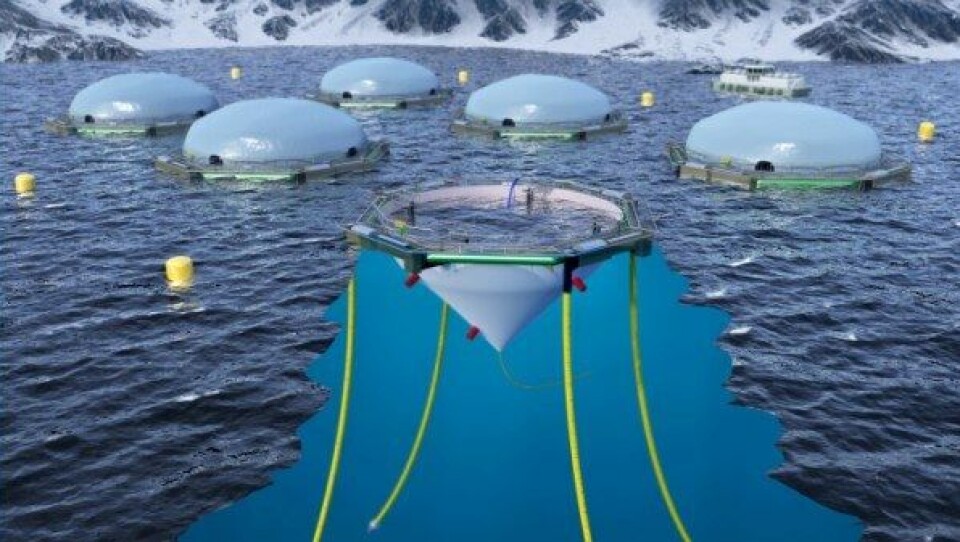

FlexiFarm treats inflow of water for all infections before entering the containment, with the aim of reducing losses in sea production, protecting the environment against undesired impacts, increasing productivity, and at the same time bringing production costs down.

The inflow of water will first be filtered and then treated by UV-light to prevent intake of lice, algae, bacteria, and virus, said Cermaq in a press release.

'Dramatically reduce losses'

"The most severe challenge for Norwegian salmon farming is the losses during production in the sea, which is mainly due to pathogens and treatments against sea lice. By treating the inflow of water for all pathogens and lice we will be able to dramatically reduce the losses of fish. We have succeeded designing a solution which addresses both the biological and environmental challenges in the industry, and which on top will be profitable to implement," said Harald Takle, R&D technology manager in Cermaq Group.

FlexiFarm's closed containment means there will be no lice or infections within the containment and no lice or infections let out from the containment, according to Cermaq. The wall of tarp will be made of flexible composite which is escape-proof and does not need maintenance during the production cycle.

Grind and spread sludge

The FelxiFarm will have a system to grind and spread sludge to avoid loads being concentrated directly underneath the farming sites. The discharge of organic material can be adapted to the capacity of the area. By grinding the sludge no entire feed pellets will be discharged from the containment.

FlexiFarm will also have an option to collect the sludge. The discharge will then pass through a filter where the sludge will be collected and transported to shore for further processing.

FlexiFarm has been developed by Cermaq together with Botngaard System, Xylem and Serge Ferrari as technology suppliers.

Oslo-based Cermaq, which farms salmon in Norway, Chile and Canada and is owned by Japan's Mitsubishi Corporation, has applied for 13 development licences for the FlexiFarm in Norway. The company claims that when developed, FlexiFarm can be used at more than 80 per cent of the existing sites in Norway, according to the maximum wave heights.

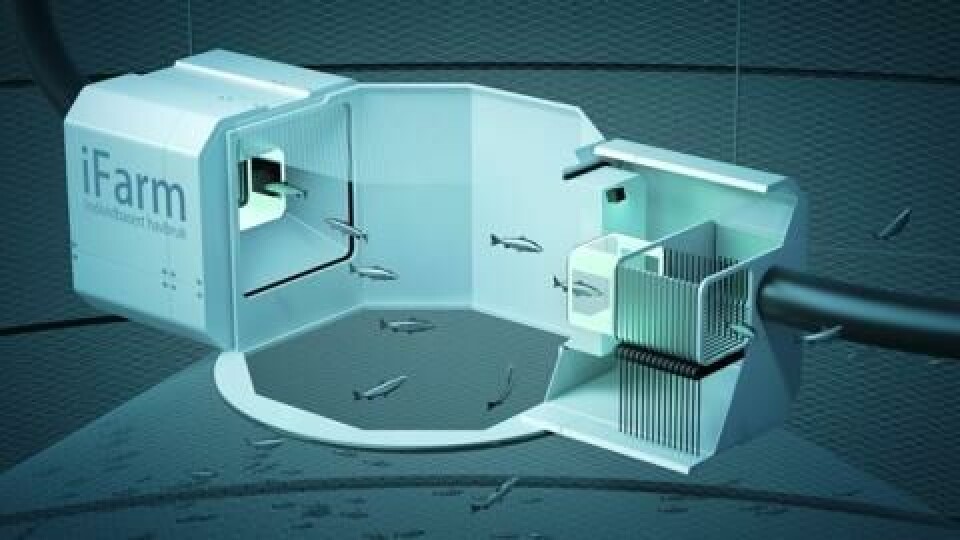

Photo recognition of fish

Cermaq recently also applied for 10 licences in Norway for another concept, the iFarm, which is based on photo recognition of fish. This allows farmers to monitor factors such as growth, sea lice, disease, lesions and others aspects that affect the health and welfare of the individual fish, according to Cermaq. In addition, it is possible to separate fish that need treatment, for example against sea lice, dramatically reducing the extent of sea lice treatments.

"In Cermaq we focus on innovations that improve sustainable farming on existing locations in coastal areas. This approach characterises this concept as well as the iFarm concept for individualised farming. Cermaq has leading expertise in farming technology and fish health, and has excellent prerequisites for succeeding in these ambitious innovations," said Knut Ellekjær, managing director of Cermaq Norway.

"It is a major goal for the development of FlexiFarm that investment and operation cost will remain low, and that the anticipated effect will ensure that production cost per kg salmon is reduced," said Magnus Stendal, general manager at Botngaard System AS.