Insect-based aquafeed ‘doesn’t change taste of fish’

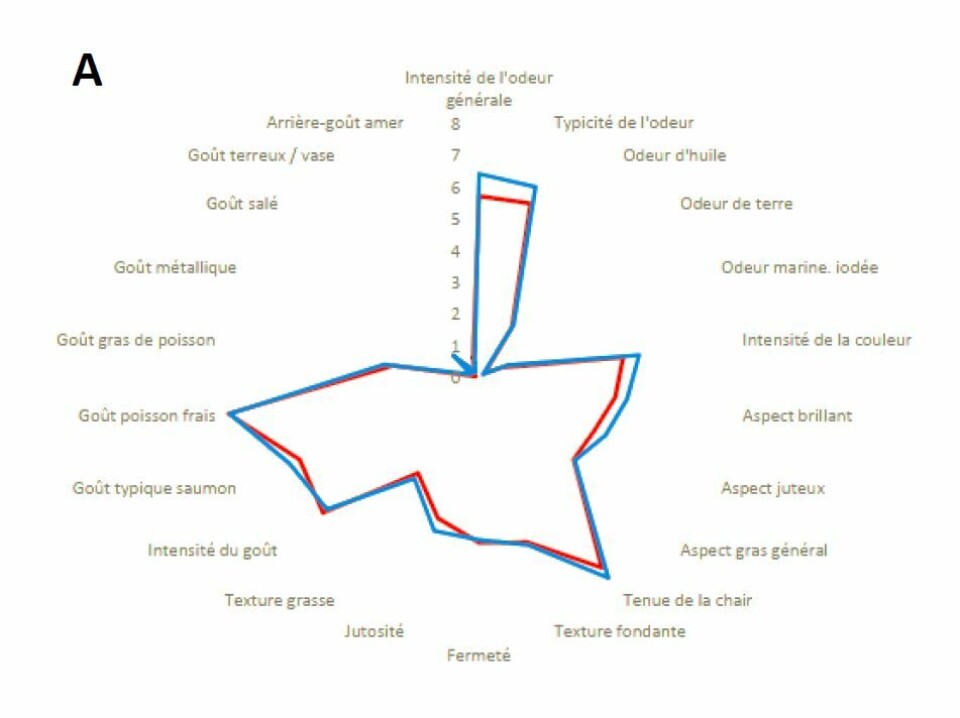

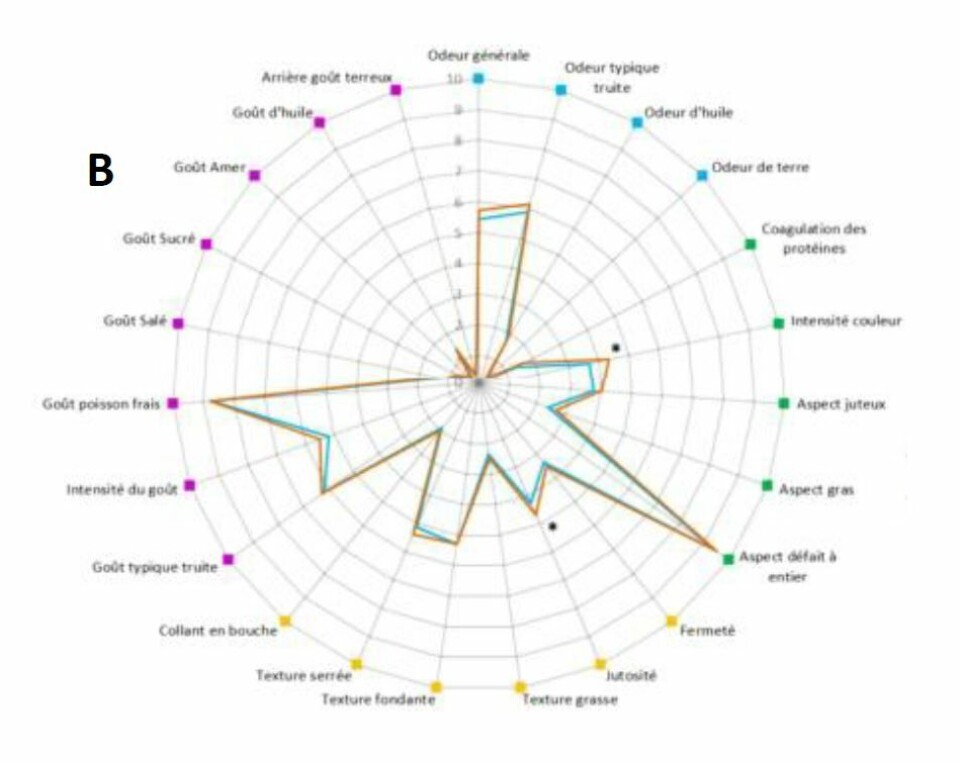

An insect-derived protein meal used in salmon and trout feeds does not change the taste of the fish, detailed taste tests have shown.

Black soldier fly (BSF) grower InnovaFeed commissioned expert tasters at Capinov, a sensory analysis company that works closely with the Label Rouge programme in France, to test fish fed with its ProtiNova protein meal.

InnovaFeed said the tests showed that ProtiNova protects, or even improves, the quality of the fish fillets.

The science of taste

“While it can be debated at a philosophical level that taste is both personal and beyond reasoning, there is a science behind measuring and quantifying the taste of produce, with well-established protocols and independent research centres that specialise in providing the results,” the company said in a press release.

“As part of developing insect-fed value chains in aquaculture, InnovaFeed and its partners have conducted in-depth research on the impact of including insect protein in salmonid feed on the quality and taste of the end product.

Trained testers

“Expertly trained taste testers have evaluated salmon/trout fillets in comparative trials. Across ~20 pre-determined parameters evaluating taste, smell, texture and appearance they have seen no significant difference between traditionally fed salmonids and insect-fed salmon and trout with the exception of a more intense colouration of the flesh and improved juiciness [in fish fed with insect-derived protein].

“When faced with a triangular test – designed to determine if expert tasters are able to identify an ‘experimental’ sample in a blind test - no experts were able to organoleptically differentiate insect-fed salmon or trout from traditionally-fed salmon.”

InnovaFeed said the results were confirmed through several independent trials across both salmon and trout and were supported by literature describing trials conducted by other actors who also concluded that there is no negative impact on the sensory experience for consumers through the inclusion of BSF proteins (Lock et al, 2015).

Lower CO₂

InnovaFeed’s aqua nutrition manager, Andrew Richardson, told Fish Farming Expert that ProtiNova has a CO₂ impact of least 50% lower than fishmeal and zero impact on the marine environment.

“ProtiNova is an excellent replacement to fishmeal based on high digestibility and balanced essential amino acid profile. Whilst it does not contain omega-3, ProtiNova contains both anti-microbial peptides (AMPs) and lauric acid, which support a healthy gut and good welfare,” added Richardson.

“ProtiNova has been used to replace up to 100% of the fishmeal in salmonid diets without an impact in performance, and our longstanding trout value chain replaces 50% in the diet.”

15,000-tonne farm

InnovaFeed is ramping up production at what it says is the world’s largest insect rearing facility in Nesle in northern France. The BSF farm, which opened in November, will ultimately have a capacity of 15,000 tonnes of protein.

The facility is co-located with starch manufacturer Tereos and the Kogeban biomass plant. The collaboration enables InnovaFeed to acquire a supply of quality substrate for the insects to feed on and, for Tereos, to locally valorise its co-products while limiting the energy needs associated with their processing.

The co-location with Kogeban enables InnovaFeed to harness the plant’s waste energy. The co-locatin project will save 57,000 tonnes of CO₂ per year.

US facility

InnovaFeed has also announced a site in the US with a planned capacity of 60,000 tonnes of protein. As in Nesle, InnovaFeed will use an industrial collaboration, in this case with ADM Decatur, the world’s largest corn processing site, in Illinois.

ADM Decatur’s corn-based co-products will be locally recycled to feed insects through connected infrastructure between the two sites. This production model will also allow InnovaFeed to use 27MW of residual energy recovered from the ADM process.