Concept takes salmon farming to a new level

A new farming concept that would see salmon grown in tanks on a platform above the surface of the sea has been unveiled in Norway.

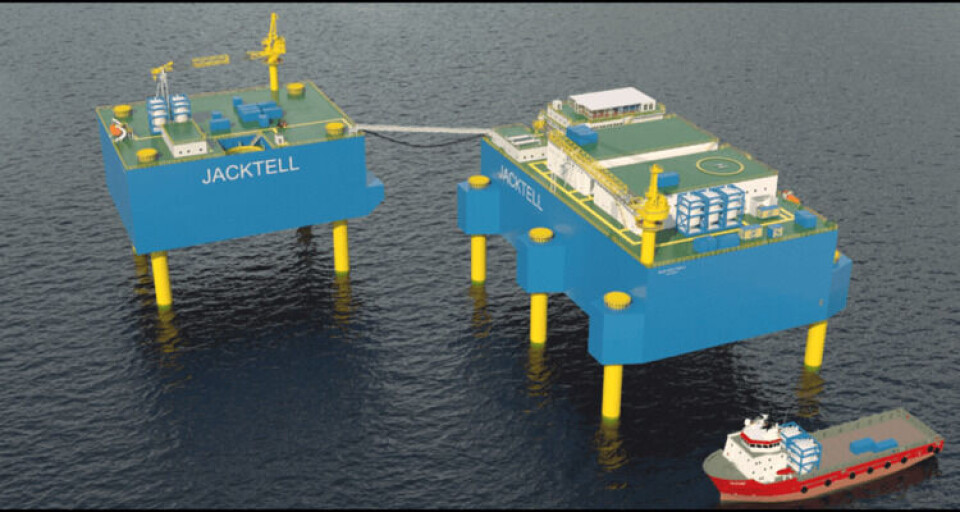

The Jacktell concept is similar to so-called jack-up rigs used for wind turbine installation. The farm can be raised above the water on six circular legs. The sea depth can be between 30 to 60 metres, and the platform would be raised around 15 metres above the surface, depending on local conditions such as wind and waves. Water would be pumped from a depth of 30m.

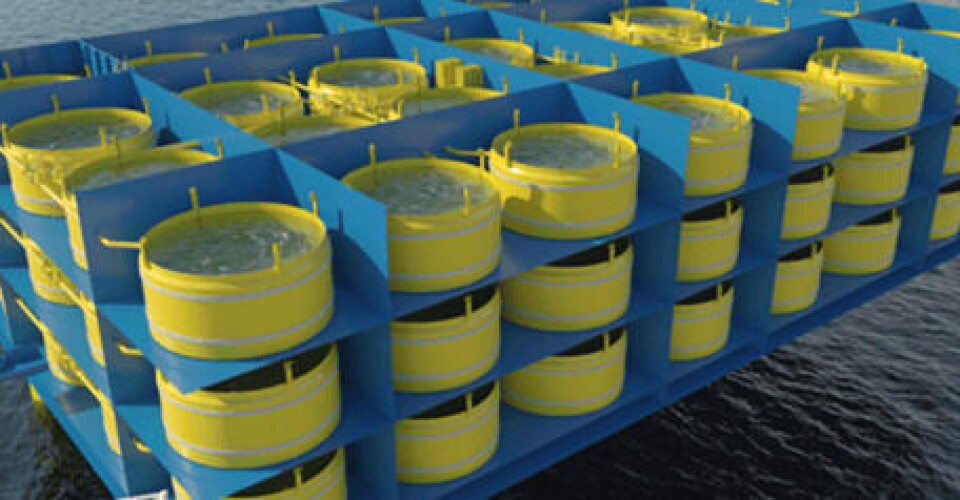

Arne Ramstad, chief executive of the company Infotronic, which has applied for Norwegian licences for the rig, envisages producing 10,000 tonnes of salmon a year in 85 tanks, connected by a flow-through pump system which uses partial RAS technology. Smolts would be grown to 1kg before being put into the facility.

All waste removed

"To get the water up to the rig, six pumps are used. Water taken into the system will first be sent through the filter with UV-control, before it is sent into the tanks," said Ramstad.

He said the water is passed through a filter where all of the waste will be removed before the water is discharged.

"In this way all water is cleaned on board. Twenty per cent of the water will be recycled and reused in the process. After this step it is cleaned again," he added.

Generate hydro electricity

By taking advantage of the steep drop from the rig to the sea, the concept also could generate hydro electricity. The plant will primarily utilise electricity from land, but it is also possible to connect it to nearby wind farms.

In a raised position, the structure could carry 60,000 tonnes of water. Ramstad thinks that the concept has several advantages.

"Firstly, it has full control of the production. The concept will have automated feeding and cameras installed in all tanks on board, so the entire process can be monitored. In addition, oxygen control and waste management will be automatically applied."

Worldwide interest

Ramstad adds that since all of the effluent is treated on board, there will also be zero emissions.

"Another advantage is that the rig can stand on sites that are currently too exposed for open cages. It will be designed for near-shore / offshore production."

Ramstad says that the concept has gained interest worldwide, and that this also opens up an opportunity to move production closer to global markets.

"The rig does not have to be in Norway if we do not get the application approved. It can be placed outside Singapore, or elsewhere that receives exported salmon," he said.

Security for workers

"By lifting the platform up from the surface, we achieve good security for those working on board. Production will not be prevented by weather."

A broad range of experts have helped come up with the design.

"This includes eight to ten engineers from Stavanger with good knowledge of the oil and gas industry. In addition, we have maintained good communication and cooperation with research institutions Nofima and Sintef, which has been important for fish health," said Ramstad.

The company Infotronic ANS is listed only as a Norwegian applicant. It is the company Jacktell Ltd which holds a patent on the concept, which was developed in collaboration with Semb Corporation Singapore and Pareto in Oslo. Ramstad said a new corporate structure was being developed. He told kyst.no that the company has applied for six licences, corresponding to a maximum permitted biomass of 4,680 tonnes.