By-products industry missing out on millions

Scotland’s salmon processing industry is losing out on millions of pounds in potential revenue by not making optimal use of by-products, according to a study by researchers from Scotland and the United States.

Scotland could increase food production from fish farming by more than 60%, increase by-product revenue by 803%, and increase the industry bottom-line by over 5%, all without having to put any new cages in the water, or use any more marine resources, say researchers led by former University of Stirling Institute of Aquaculture (IoA) student Julien Stevens.

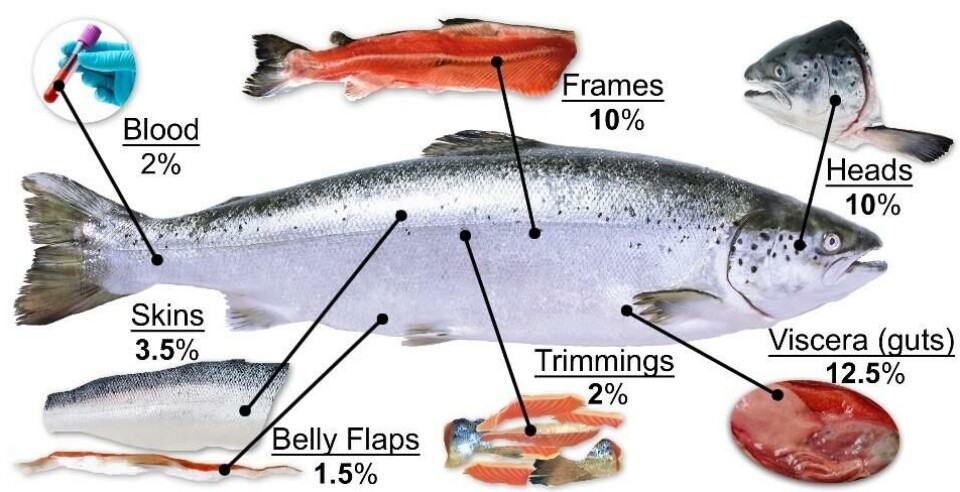

Their findings show that many of the by-products currently mixed together by processors and sold cheaply to local rendering and hydrolysate facilities for animal feed would more than double in value if they did not mix them, and instead sold them as the component parts: trimmings, heads, frames, viscera, skins, and belly flaps.

The researchers said that during processor surveys, a few large and medium Scottish facilities were identified as already implementing these innovative practices to increase value-addition of their by-products. But the current sector profile of many small to medium sized processors with limited economies of scale was a constraint, coupled with a need for a suitable infrastructure for the sorting, grading, storing and transporting of by-products and for using them strategically.

Primary products

The work was carried out by researchers at the IoA and the University of Massachusetts in Boston, and funded by the International Fishmeal and Fish Oil Organisation, IFFO.

Working with 2015 figures, the research concluded that directing 77% of the annual whole fish production towards human consumption - combining primary products (54% yield) with the maximum potential by-product food yield (~ 23%) - results in 132,171 tonnes of food.

The remaining by-products, minus blood water (4.3%), are then utilised in the production of fishmeal and fish oil, and subsequently used in aquafeed for farm raised marine species. In this example, accounting for that material in feed for European seabass and gilthead seabream, would result in 148,691 tonnes of total edible yield compared to the original production of 92,081 tonnes of salmon.

FI:FO calculations 'simplistic'

The authors also commented on how current Fish in: Fish out (FI:FO) models do not adequately take into account how finfish are utilised and therefore the efficiency of marine ingredients utilisation in aquafeeds.

IFFO’s Neil Auchterlonie noted that “current research highlights that FI:FO calculations tend to be simplistic, nether taking into account the nutritional contributions from fishmeal and fish oil beyond protein and energy, nor do they account for the end product other than the edible portion. FIFO ratios have therefore tended to underestimate the contributions from fishmeal and fish oil.”

A longer version of this article is included in the upcoming edition of Fish Farming Expert magazine, and the scientific paper “The rise of aquaculture by-products: Increasing food production, value, and sustainability through strategic utilisation”, published by Marine Policy, can be read here.