A natural solution to RAS discharge water

Scientists in Finland are progressing efforts to find a low-tech method of filtering discharge water from a recirculating aquaculture system so that it can go back into the RAS.

The Natural Resources Institute Finland (Luke) has taken its lead from trout farms in Denmark that use discharge management systems such as wetlands and woodchip beds.

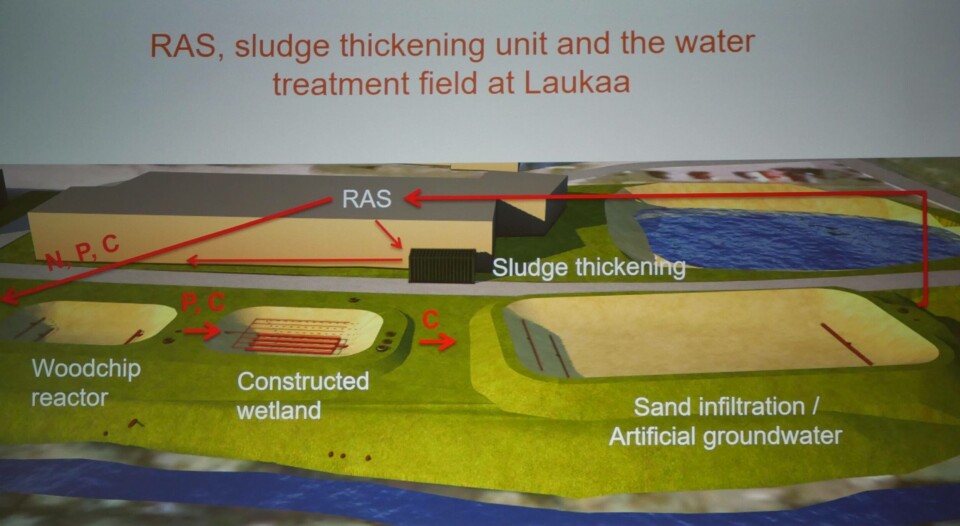

To develop the concept further, researchers at Luke have built a field-scale pilot system with an annual capacity of approximately 14 tonnes which includes a hybrid solution of a woodchip bed, constructed wetland and sand filtration.

They aim to use the three-step system to remove enough effluent nitrogen, phosphorous and organic matter to allow the water to be re-used, reducing the need for freshwater intake.

New licences

Speaking at the Nordic RAS Workshop held in conjunction with the European Aquaculture Society’s Aquaculture Europe convention in Berlin, Luke researcher Jouni Vielma said it was hard for Finnish fish farmers to get a new licence without efficient discharge management.

He added that Luke’s system was inspired by Danish trout producer FREA A/S, which farms 2,000 tonnes per year at a plant established without connection to watercourses. Instead, the water for production is obtained from underground sources in the surrounding area.

Vielma explained that FREA discharges its water into fields then takes the water back from five metres below the surface.

Lab studies

Luke researchers first carried out two lab studies on individual RAS, establishing side-loops of woodchip and sand filtration units.

A control RAS without the treatment system received lake water at 500 litres/kg of feed. In the first experiment the treatment provided 250 or 400 L/kg of the replacement water, decreasing the new water intake to 250 or 100 L/kg. The woodchip beds had 57 and 91 litres of birch chip with a hydraulic residence time (HRT) of 36 hours.

The surface-fed sand filter had effective porosity of 0.35, and 80% of the height was water-saturated conditions, with a HRT of 1.2 days.

Nitrate removal in the woodchip beds was insufficient, declining throughout to 9g N/m³ at the end of the 10-week experiment.

In the second experiment, control RAS and RAS with the treatment system (new water 100 L/kg feed) had been running for 29 weeks.

Based on the lab experiments a field-scale pilot system was built in which woodchips take out nitrogen from the RAS water, constructed wetland removes phosphorus and the sand filtration removes carbon.

The total volumes of the woodchip bed and sand filter are 50m³ and 650m³ respectively, and the vertical-flow constructed wetland, made of common reeds, has a surface area of 135m². The woodchip bed is designed so that the top 50cm stays dry to serve as insulation in the winter.

Challenging to find balance

Water volumes, and thus the time water spends in the system, can be adjusted.

Challenges in the operation of the system include finding the balance in efficient denitrification while avoiding sulphate reduction and N2O (nitrous oxide) formation in the woodchip bed, and also avoiding harmful metal dissolution in the anoxic (oxygen-free) sand filter.

Careful study is also needed to find suitable operational parameters in winter.