Salmon farmers 'wasting money on moorings'

Scottish salmon farmers could be paying up to 25 per cent too much for mooring systems because of a trend to over-specify equipment, a moorings expert believes.

Lawrie Stove, of Oban-based AquaMoor, said an understandable desire to make sure sites are secure, coupled with what he regards as a lack of a proper engineering analysis, had led to a “culture” of buying bigger anchors, ropes and hardware than required.

Stove was speaking after finding that his company’s engineering and analysis expertise was attracting more interest at home and abroad than expected, following AquaMoor’s participation at the Aqua Nor trade show in Trondheim in August.

He said the engineering consultancy was “part of the complete package we had on display at Aqua Nor, where our message was that there’s a better way of specifying moorings where you conduct a proper engineering analysis of a design based on a site survey, and apply appropriate engineering standards to the dimensioning of the moorings”.

Precise load distribution

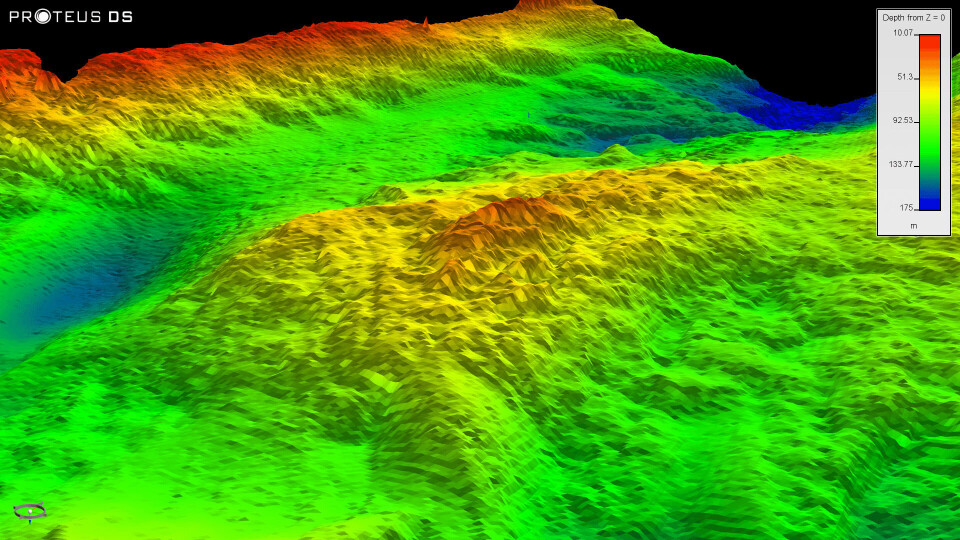

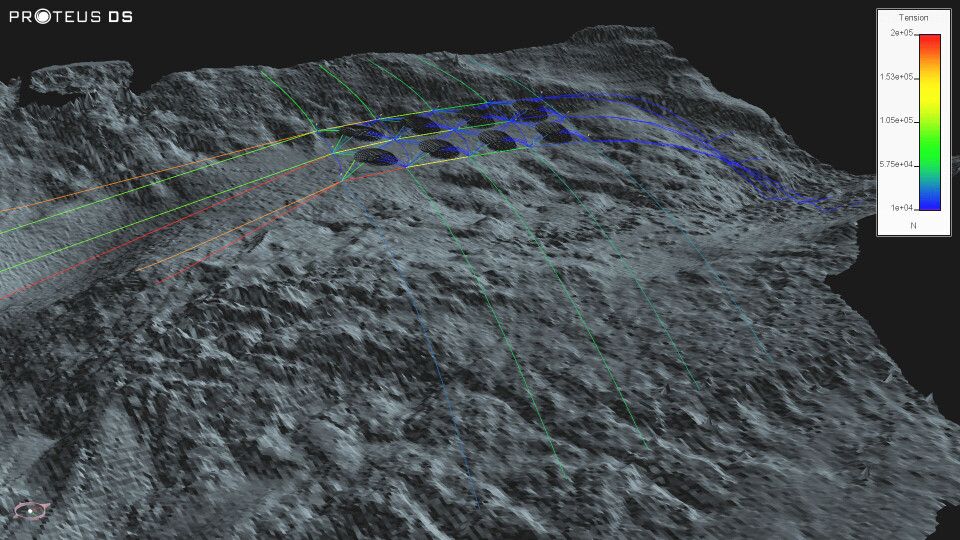

AquaMoor uses a Canadian modelling software program called Proteus DS, similar to the AquaSim software used in Norway, to calculate precise load distribution on mooring lines.

“The key reason for using it is because farmers should be offered moorings that are fit for purpose, and not with massive factors of safety built in because you don’t really know what you’re doing,” said Stove.

“There’s been a culture of people saying ‘that might not be big enough, let’s make that anchor or that rope a bit bigger’. There is a lot of over-specifying going on.”

Stove, a member of the Scottish Technical Standard (STS) Steering Group, added: “The Scottish standard has been introduced with recommended factors of safety, but in some cases I think that has led to suppliers saying ‘if we are applying the STS standards we need a factor of safety of three on the rope, over and above our own suggested factor of safety, we can’t now offer you the 38mm, it has got to go up to the 48mm, which by the way is a bit more expensive’.

“We’d rather offer an assured engineering analysis so we’ve actually got something we can hang our hat on and say we’ve done a thorough independent analysis using a software program that’s accepted in the international aquaculture industry, and widely used in Norway and Canada, and should be acceptable to anyone anywhere else in the world because it’s compliant with best practice.

“If the answer from that analysis says 38mm rope is fine in terms of its capacity and compliance, then it is an appropriate dimension to specify.”

Management systems for moorings

AquaMoor has received enquiries to model mooring systems from Norway, Denmark, Finland, Malta, Iran and further afield from Chile, Singapore, Mexico and India. Stove said about half its consultancy work was in Scotland, and half abroad.

He added that the company remained very much interested in supplying full mooring systems. “We’ve been made aware of over £3 million of projects for complete mooring systems after Aqua Nor, most of those in Scotland and for 2018 installation.

“What we’ve found in the meantime is people are saying they want our consultancy services to look at the survey, design and analysis of sites.

“We’ve also been investigating management systems for moorings maintenance that can deliver ongoing assurance for the full service life of a correctly dimensioned, properly installed mooring system.

“We have a user-friendly ‘point and click’ program that will take you from an interactive mooring plan straight to the product certificates specific to the selected component. It will generate alerts and checklists when inspections are required and can record inspections completed and maintenance work when done.”