Going with the Flo

The world’s most sophisticated ocean simulator opened its doors to a group of key figures from Scotland’s aquaculture industry this week.

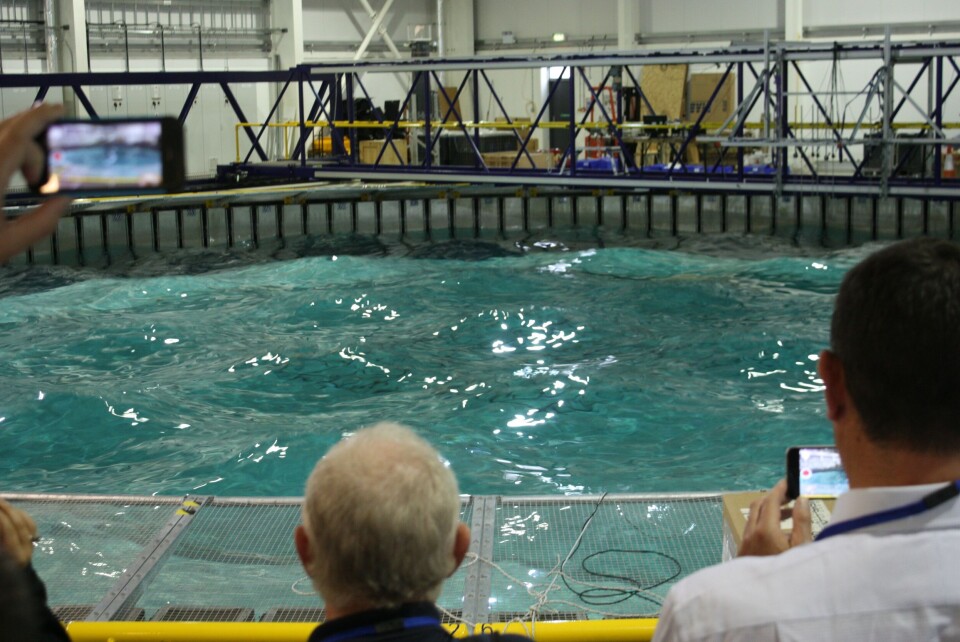

Participants in a Scottish Aquaculture Innovation Centre (SAIC) workshop, who spent Wednesday morning discussing the role engineering could play in the development of the aquaculture industry, were treated to a tour of FloWave – a facility that is deemed to be the best in the world for ocean simulation.

Designed primarily for the development of offshore renewables systems, the tour of the £12 million facility – which opened in 2014 and is located in the University of Edinburgh’s Kings Buildings complex – reinforced the belief that it also has great potential for the aquaculture industry.

Indeed, as Dr Jamie Grimwade, who is in charge of technical sales and business development at the facility, pointed out to Fish Farming Expert, it has already been used in the development of one aquaculture-related project.

“Our first customer, back in April 2014, was Albatern – a company that was investigating the feasibility of integrating wave-powered electricity generation with fish farm sites, not only to power the feed barges on the sites themselves, but also to put any surplus back into the grid.”

Although the Albatern project, which went on to be tested at Marine Harvest’s site off the Isle of Muck, has not yet been deployed at full commercial scale, it clearly doesn’t discount the facility from being used for other aquaculture-related tests – not only is it the only one of its kind in Scotland but it is also deemed to be the best in the world.

“It’s a unique facility,” Jamie continued, “not only can we conduct simultaneous wave and current tests but the circular nature of the pool means that we can run waves from any direction, or even different directions at the same time, which makes it much more representative of genuine ocean conditions.”

And it can be set up to experience a huge range of conditions – recreating pretty much any sea state that could be experienced in British waters, and indeed anywhere in the world.

“It’s usually set up to be a 1:20 scale test facility and, at that ratio, this means we can test structures up the equivalent wave height of 10m. If we change the ratio to 1:40, we are testing up to 20m wave heights – we can create conditions as extreme as anything that could be experienced around the UK continental shelf and beyond,” Jamie explained

As well as waves the facility is also able to produce current speeds of up to 0.5m/sec with waves (or up to 1.5m/sec without waves) and this could also be used to test the effect of currents on net shape. Another potential application would be to test the viability of personnel transfer to/from exposed sites in rough weather.

Why test here?

Stuart Brown, CEO of the facility, is keen to develop stronger links with aquaculture.

“FloWave is the world’s most sophisticated ocean testing facility by a country mile, and it would be great to be more heavily involved with the aquaculture sector and to help the industry to grow not only its technical expertise and capability, but also its volume and economies of scale – otherwise it [aquaculture equipment design and manufacture] could be another industry that we risk losing to other countries through contraction and consolidation,” he told Fish Farming Expert.

The experience of the FloWave team should make setting up and conducting tests relatively easy to organise too.

“We have a dedicated team of staff to help deliver the tests and, while some clients build their own models prior to testing, but we also have model making capabilities here,” says Stuart.

“To innovate you need to make mistakes and this is a great facility to test out new ideas – you can work out whether concepts are worth pursuing fairly quickly, and also which are not worth continuing spending time on,” he adds.

Although, as Jamie and Stuart admit, hiring the facility is by no means cheap, there are a number of reasons why such rigorous testing is worthwhile in the long run.

“The main point is risk reduction,” explained Jamie, “although it might be relatively expensive to rent the facility, it is much less costly than having equipment fail in the field, while increased testing is also likely to have positive insurance implications.”

Industry reaction

Those taking part in the SAIC event and who came on the tour represented a wide range of companies and institutions, including representatives from salmon producers such as Scottish Sea Farms and the Scottish Salmon Company; equipment providers such as Gaelforce, W&J Knox, Aquamoor, Ace Aquatec, TFI Marine, Hook Marine and Pulcea; and research establishments such as SRUC and the Universities of Edinburgh, Dundee, Stirling and Heriot Watt.

All were mesmerised by the extraordinary display of the facility’s capabilities, as Facility Manager Dr Thomas Davey managed to create all manner of water movements using the facility’s 168 wave makers/absorbers to great creative effect.

Meanwhile SAIC’s Robin Shields was enthusiastic about the morning’s gathering, saying: “It’s been great to achieve such positive interaction between engineering experts and aquaculture practitioners this morning. The SAIC team look forward to new academia-industry collaborations that will help resolve key industry challenges.”

And Heather Jones, CEO of SAIC, added: “We’ve been really pleased by the level of participation in today’s event, the two different groups in the morning – one of which was discussing engineering-related lice treatments and the other looking at how engineering could open up new, high energy sites – were busy trading plenty of ideas and it’s great to see people from different companies sharing their thoughts so openly.

"The whole interactive industry-academia workshop concept, which SAIC has been running since inception, is novel and ground-breaking. It's been singled out for praise in a recent submission by a Scotland-wide universities group commenting on work of Scotland's eight Innovation Centres. I hadn't realised before how much the academic community welcomes SAIC bringing clearly articulated industry needs to light. Our 'connect and collaborate' workshops enable people from businesses and companies to bring novel solutions to bear to support the Scottish aquaculture industry's growth."

Future projects

The next aquaculture project to use the FloWave may well be one that looks into how nets can be designed to withstand more extreme currents.

“Edinburgh’s School of Geosciences has applied for funding to analyse how net deformations caused by high energy tidal currents can be countered by altering the structure of the nets – perhaps using hydrofoils to correct for net deformation,” says Jamie.

Whether this project gains funding or not, it is clear that Scotland possesses a world class testing facility in FloWave and it will be interesting to see whether the aquaculture industry is able to put it to good use.