Enhancing aquaculture by-products

By Philippe Sourd Aquativ business development manager

While the fish farming industry needs to keep growing, the amount of marine raw materials available from fisheries is unlikely to increase. Thankfully, however, better knowledge of farmed fish nutritional requirements, genetic improvements, the use of alternative ingredients and the application of smart technologies to refine raw materials have all led to a tremendous reduction in the amount of marine raw material used in the culture of carnivorous fish. The percentage of fish meal in salmon diets has fallen from 30% to 15% in the last 10 years (Nofima). A kilo of salmon now requires 0.7kg of fish meal to be produced rather than 4.4kg in the late 90s (according to Nofima report 36/2014) as today’s salmon diets contain just under 20% marine proteins on average. Nonetheless, marine proteins and oils are still required to meet the biological needs of fish and shrimp as well as to fuel the farming industry’s growth. Improving the quality and bioavailability of actual marine ingredients is paramount, so is the use of aquaculture and fisheries by-products. If aquaculture is growing, then so is the generation of by-products: these can’t be wasted. According to OECD-FAO Agricultural Notebook 2012-2020 and IFFO figures, 2 million tonnes of fish meal and 400,000 tonnes of fish oil are currently extracted from aquatic by-products. In 2012, according to research by Nofima, around 320,000 tonnes of fish meal were used in Norwegian salmon industry, of which 25% came from trimmings and silage – a proportion that is growing. In Chile the figure is close to 15% while in Canada it is 100%. Predictions indicate that this trend will increase across the global salmon industry. The ongoing development of modern food processing technologies has sparked a greater interest in the marketable raw materials derived from fisheries by-catch and seafood processing leftovers which have long been discarded as waste or processed into low market value products such as silage which is then used as fertilizers.

Conversion of these nutrient-rich feed stuffs into aquafeed is now common, but can be further enhanced by more modern and sophisticated technologies, including enzymatic hydrolysis. Enzymatic hydrolysis biotechnologies have been developed to improve the functional and nutritional properties of the aquatic by-products through the conversion of raw, fresh proteins into smaller biologically active peptides. The salmon processing industry is heading towards more sophisticated technologies than silage, to create increasingly refined uses for by-products – including feed, food, pharmaceutical and cosmetic applications. Different programmes are under development in Norway or have already been successfully completed. Similar value creation processes are in place for other by-products from aquaculture, such as shrimp. Ecuador produces close to 300,000 tonnes of Pacific white shrimp (Pennaeus vannamei) per year across its 3,000 extensive or semi-intensive farms, operating in 2-20 ha ponds at low densities, mainly in Gayas and El Oro regions. Shrimp diets contain 10-15% fish meal, of which 60% is made from aquatic by-products, and they contain less than 3% fish oil. Shrimp achieve an FCR of 1.5-2 and take 3-5 months to reach harvest size (20 to 30g). They are harvested every spring tide to be processed prior to export to the EU, US and Asia. Ecuador’s shrimp processing industry thus generates significant volumes of by-products in the form of shrimp heads and shells, which may represent up to 50% of the processed material. Shrimp by-products contain valuable components – such as protein, chitin, cholesterol and astaxanthin – all of which are of high value for aquafeeds. Those leftovers may be used in several ways. Composting shrimp waste into fertiliser is one example of use. Shrimp head meal production also allows re-using some shrimp proteins back into aquaculture feedstuff. Crustacean protein hydrolysates have long been used in aquafeeds as potential protein sources or as dietary supplements in small amounts for improvement of diet palatability. Indeed, recovery of shrimp “waste” by enzymatic hydrolysis results in the formation of biologically active peptides with documented pharmaceutical and growth-stimulating properties.

Prerequisites The raw materials collected from processing plants must fulfil several stringent criteria prior to further processing into hydrolysates. Suppliers must obviously comply with regulations and observe strict specifications. In return for meeting the required criteria suppliers get a premium price for their by-products against other outlets. In the end, few pass the selection criteria but the extra money made from by-products that have been handled properly provides a strong incitement towards delivering well cared for by-products that will no longer be considered as “waste”.

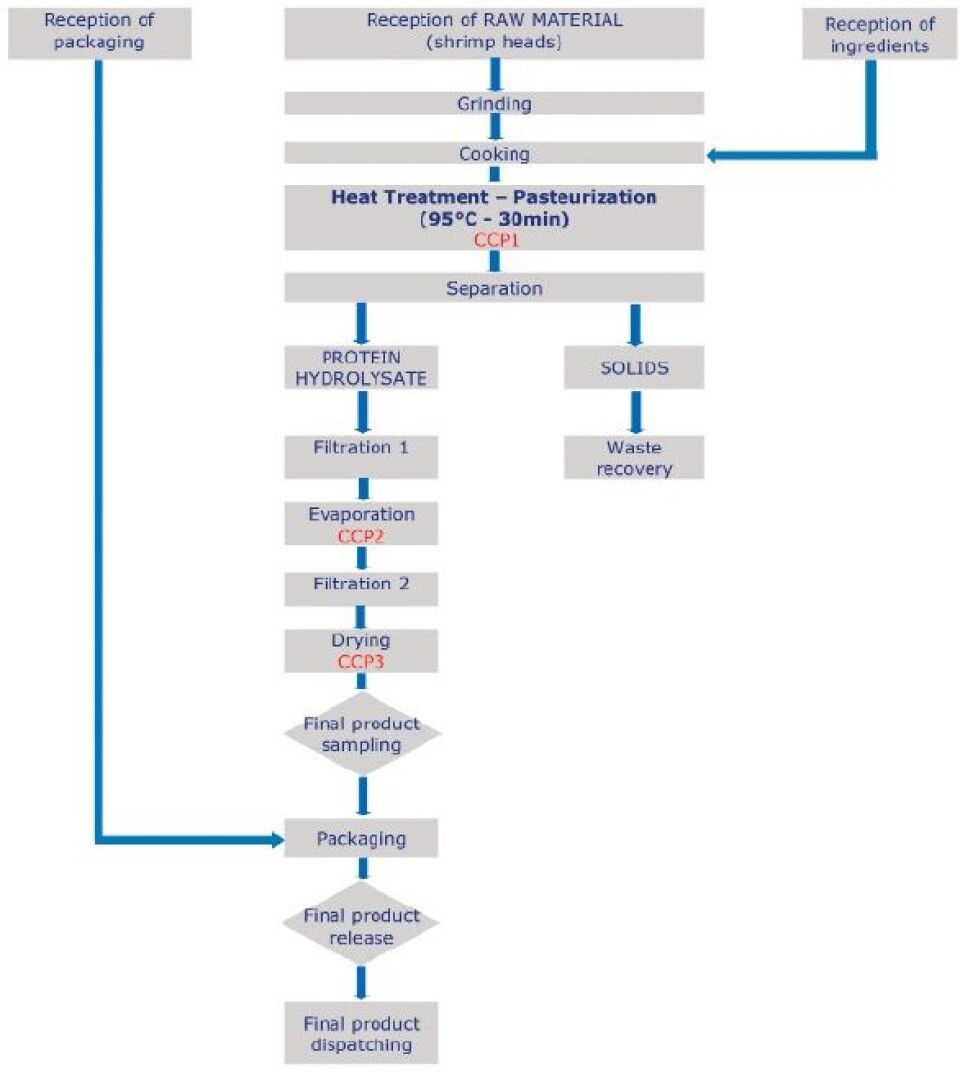

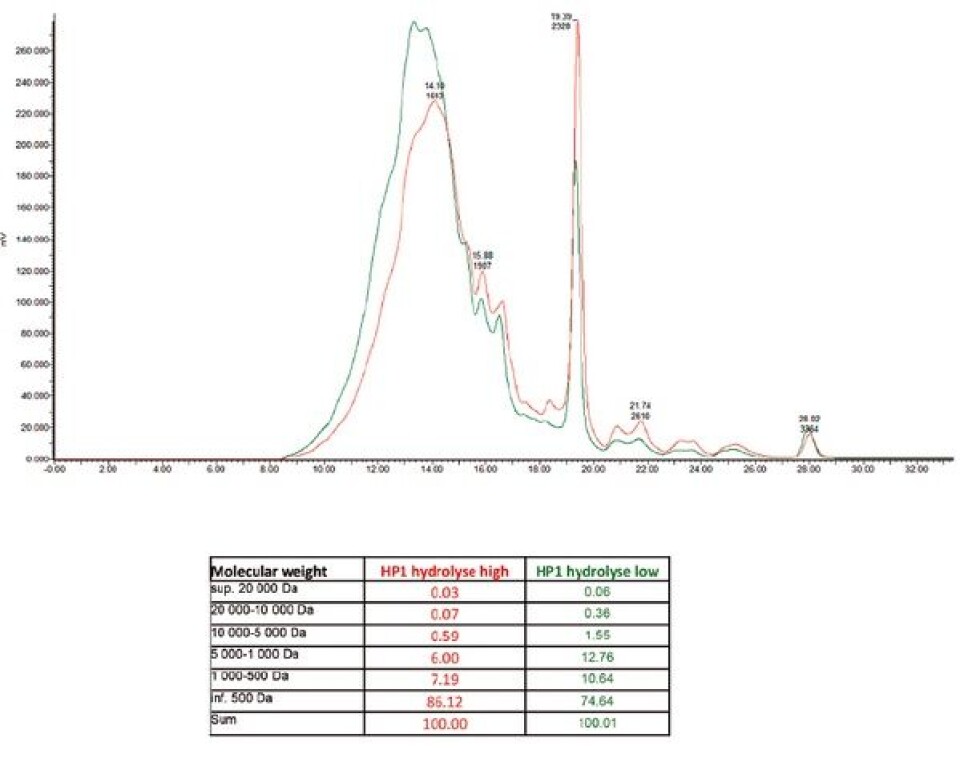

Process As shown on the flowchart, the process starts with grinding of the shrimp heads. Temperature control and timing are very important in this step so as to avoid bacteria and undesirable biogenic amines building up. Once ground, the mix is poured into a 15 tonne capacity double envelope bioreactor where protein hydrolysis with exogenous enzymes will occur. The choice and doses of enzymes are major drivers. So is the bioreactor design (heating/agitation). They will obviously define reaction conditions as well as the end product’s profile and thus its performance. Only the latter shall dictate the enzymes choice, towards the best possible ingredient – ie with the desired variety of peptides and a repeatable product profile batch after batch. The peptide profiles below (Fig. 1) are obtained with different enzymes. It is paramount to determine which will deliver the best biological performances when used in aquafeed. In-vitro and in-vivo testing facilities with high screening capacities are therefore vital. The hydrolysis reaction is carried out under very specific and highly standardized agitation, duration, temperature and moisture control conditions. Any deviation from the standard recipe will result in a change of enzymatic activity and reactions and therefore, again, change the end product’s profile and thus performance in aquafeed. The whole process is under PLC control.

Once the enzymatic hydrolysis is over, the temperature is slowly increased so as to undergo a pasteurization process of 30 minutes at 90°C. Besides sterilizing the product it also de-activates the enzymes, stopping the hydrolysis. The careful filtration that follows allows the shrimp shells to be separated out and discarded from the feeds. The shells – which are mostly made of chitin, carbohydrate and minerals – may later be exploited for further refining into other bioactive compounds (chitosan and glycosamineglycan) for feed, food or even pharmaceuticals and cosmetic applications. Concentration and spray drying follow. The advantage of spray drying is that proteins, peptides, fat and all other nutrients are dried at a low temperature. This preserves the integrity of those nutrients and thus the final product functionalities. It also produces a very homogeneous powder with regards to particle size. Finally, a fine light pink (due to astaxanthin presence) hygroscopic powder is obtained and ready to be used in aquafeeds. Besides automated controls, it goes without saying that the entire process undergoes a strict manufacturing and hygiene process and qualifies for HACCP, so as to comply with modern aquafeed quality requirements and therefore the product can be exported worldwide. Final analytical tools – such as NIR technology to verify proximal analysis and HPLC to verify protein profile – must be available on site and run by qualified and experienced technicians.

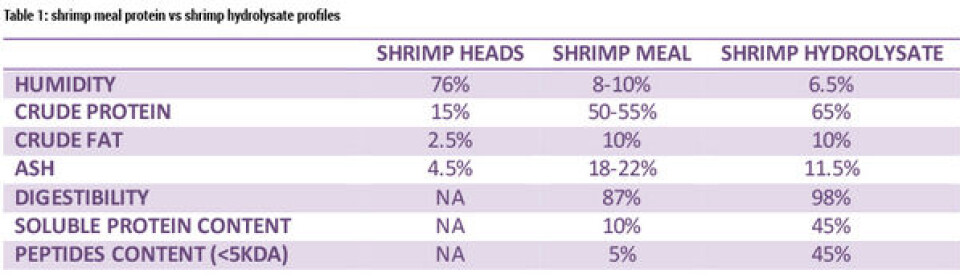

Protein profile and benefits When looking at shrimp meal protein profile vs shrimp hydrolysate’s (Table 1), the differences are obvious. The process increases protein content in the end product and renders them more soluble and more digestible for fish. The very high fraction of small peptides and other nitrogen soluble compounds – such as free amino acids, nucleotides and amino acid derivatives like taurine or betaïne – contributes to enhanced feed intake in fish and shrimp when added to the diet. These small peptides also have bioactive properties (antioxydative, antimicrobial, immunostimulant, gut health) that bring benefits for fish, shrimp and even human health. These biological benefits are strongly correlated to the peptide profile obtained after the hydrolysis. Hence the importance of screening the biological value of the many profiles that can be obtained with many different enzymes and processes, to find as effective a final product as possible. And hence the importance of mastering the bio-process to standardize the end product.

From raw material selection to obtaining a highly effective ingredient for fish feed, the path requires long term investments. Raw material suppliers must understand the importance of their role as well as benefit from efforts granted for better by-product care. Controlled hydrolysis technology creates a high value product from substances that have too long been considered as waste – provided the process is controlled and the end products are thoroughly screened for their biological value. The aquaculture proteins refined and enhanced as such can be further used for aquafeed, without being fed to the same species, allowing the industry to spare fragile and limited marine resources while preserving or enhancing the biological performances of cultured fish.