Shedding northern light on cold climate smolt growth

What’s the best on-land system for growing smolts, flow-through or a recirculating aquaculture system? The answer is both, at least for Laksefjord AS, the Finnmark smolt producer owned by Lerøy Aurora.

The company uses a combined system, and also uses both fixed bed and moving bed biofilters, and both freshwater and brackish water, chief executive Bjørn Hovrud told the Nordic RAS conference held in Berlin last week.

Smolt production at the site at Lebesby in the far north of Norway began in 1987, and the company became part of Lerøy in 2005. Since then, $150 million has been invested and the plant now has an annual production of 4,800 tonnes.

The site has 12 independent RAS systems and a tank volume of 21,300m³.

Heat pumps

“For seven months of the year the freshwater coming in is less than 0.5°C,” said Hovrud.

“We got our first RAS five years ago and also invested heavily in heat pumps in the flow-through sections.”

The investment has allowed Hovrud and his staff to take complete control of the process. The water temperature is now 8°C in the hatcheries and 14°C in other parts of the plant.

There is no natural light inside. The fish are exposed to 24 hours of light per day, apart from six weeks for winter signal.

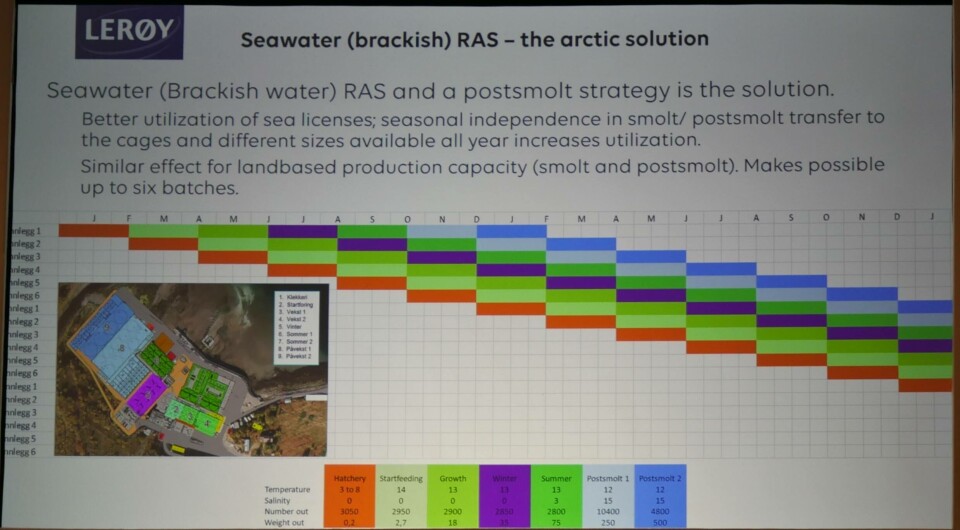

Year-round supply

It takes 10 months from when the fish are hatched to when they are set out in cages.

A problem Lakesfjord and Lerøy faced was that Norway’s regulations stipulate that smolts cannot be transferred from freshwater to sea water if the sea temperature is lower than 7°C, which in Finnmark is the case for six months of the year.

Such limited transfer opportunities made it difficult to use sea sites efficiently and increase biomass.

“The solution is sea water or brackish RAS,” said Hovrud. “It is not illegal to transfer small salmon that are already in the sea.”

It means Laksefjord can supply fish year-round if required.

Biofilters take time

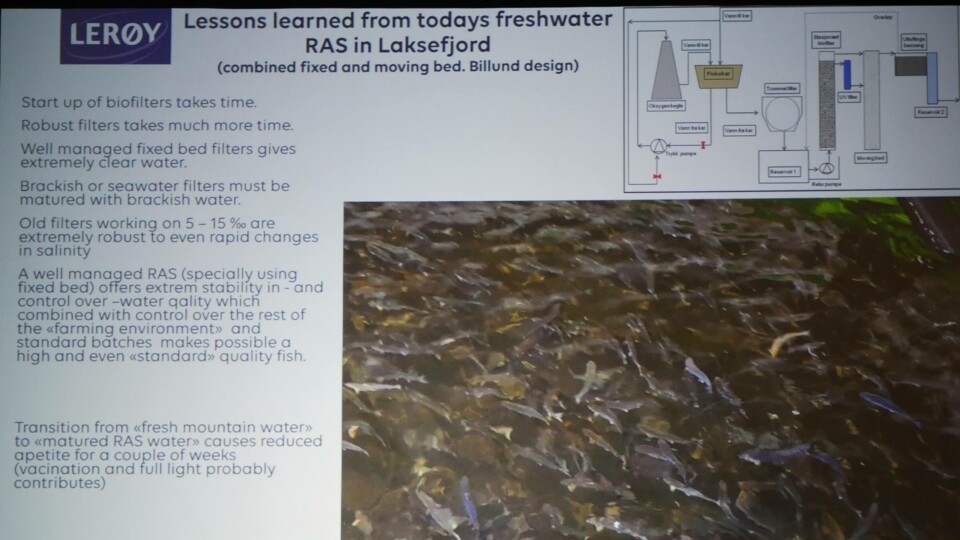

The smolt plant’s staff have learned a lot about what technology works best for brackish water.

For one thing, start up of biofilters takes time, and brackish or sea water filters must be matured with brackish water.

The company uses only fixed bed bio-filters for brackish RAS. Old filters working on salinity of 5-15 parts per million are extremely robust to even rapid changes in salinity, said Hovrud, and a well-managed RAS using a fixed bed filter offers extreme stability in – and control over – water quality.

The Laksefjord boss said transition from fresh mountain water to “matured RAS water” causes fish to have a reduced appetite for a couple of weeks, although vaccination and full light probably contributed too.

Low mortality

The facility has produced four test batches of post-smolts over the last four years, with good results. In each batch 1 million smolts were transferred to brackish water in late October each year.

The fish grew from 80 gram smolts to 250 grams in two months in 12°C water and 24-hour light. The specific growth rate average over the period was 2%.

Accumulated mortality over the period ranged from 0.02% to 0.07% for the different tanks.

The fish were transferred to sea in late December / early January, with the sea temperature in the wellboat approximately 3.5°C.

Average accumulated mortality from cage transfer to harvest was 3.7%.