RAS threat to long-term Scottish growth plans

Increased development of recirculating aquaculture systems (RAS) in markets such as China, the Middle East and in Europe could substantially limit the long-term potential for further growth in Scottish salmon production, a new study for Highlands and Islands Enterprise concludes.

But the recent proliferation of RAS projects is unlikely to cause an immediate threat to net-pen farming in Scotland or elsewhere, the study’s authors say.

The study, contracted by Glasgow-based consultancy Ekos, updates a 2014 report Review of Recirculation Aquaculture System Technologies and their Commercial Application and has been written by the review’s authors: Stirling University Institute of Aquaculture experts John Bostock and Francis Murray, and David Fletcher of RAS Aquaculture Research Ltd, with additional input from Maddi Badiola (Meet-Energy).

The authors say that while leading salmon aquaculture companies are all making strategic investments in RAS, this is mainly for juvenile production. An increasing proportion of the smolts in Scotland are from tank-based systems (63% in 2016 compared with 40% in 2012).

Worldwide, RAS-based grow-out projects “based on a mix of optimistic technology promises and ethically driven enthusiasm for land-based farming” have experienced a range of technical, financial and market problems and have either failed completely or are operating at a loss.

“Nevertheless, there is substantial momentum and lessons are being learned and technology is developing at a faster rate than when previously assessed in 2014,” say the authors.

They say land-based RAS could provide Scottish farmers with an economic means of growing post-smolts to between 250g and 1kg, shortening their time in the sea and their exposure to sea lice and disease.

New species development

RAS also offer opportunities for new species development in Scotland, with examples including sturgeon (caviar), yellow tail, sole, tropical shrimp, and spiny lobster. However, these are generally high value products for which domestic markets may be more limited, point out the authors.

On-land farms could also help the Scottish industry if it loses the “social licence” necessary to achieve ambitious growth-targets due to perceived conflicts with environmental and conservation targets, the study says.

“For this reason, combined with steadily maturing technology and new species opportunities, it is anticipated that aquaculture production using recirculated aquaculture systems will gradually expand in the coming years,” write the authors.

Social licence

They point to a “relatively small, but highly persistent group of lobbyists against cage-based fish farming” and say that, while market demand for salmon remains resilient, amplification by lobbyists of the environmental issues associated with cage-based aquaculture does threaten its social licence to operate.

The study also examines the relative costs of RAS and net-pen farming, as well the operational reliability and health management of on-land facilities.

“In principle, RAS should provide a more secure environment for the stock without the risks of environmental stressors including storms, predators, algal or jellyfish blooms etc,” write the authors.

Problems in practice

“They should also provide substantially better biosecurity, resulting in lower mortality levels or welfare issues associated with disease.

“In practice many problems have occurred.

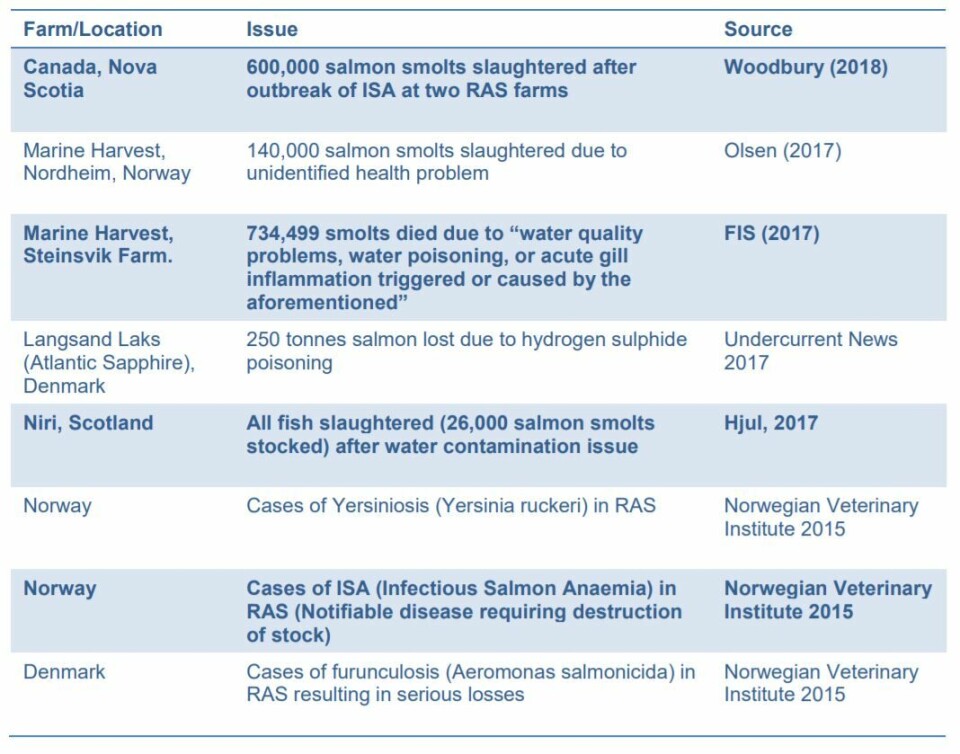

“Due to commercial sensitivities there has been relatively little documentation of disease problems in RAS or losses caused due to equipment failures. It is likely that almost every new RAS has experienced a problem resulting in complete or almost complete loss of a production cycle.”

The report includes a table listing several cases where fish have been lost due to problems in RAS (see right).

On the issue of costs, the study says that although capital costs are higher for RAS, the direct operating costs of onshore RAS are generally competitive with cage farming.

The authors point out that the most important direct operating cost for all intensive grow-out operations is feed, comprising up to 60% of direct variable production costs.

Superior FCR

“There is relatively little published data, but assuming normal operations RAS should provide superior feed conversion rates (FCR) based on lower mortality rates and lower direct feed loss,” they say.

“The energy requirements for RAS are frequently discussed as a constraint, but generally constitute less than 10% of direct operating costs and are generally decreasing with scale (whilst feed increases as a proportion of total operating costs).”

Energy requirements do however become much more significant if heating or cooling are required.

Lack of experience

One difficulty for the development of new RAS is that experienced operators, especially in application of marine RAS technology, are in short supply, say the authors.

“Experience on large RAS farms in excess of several hundred tonnes annual production is essential to get to grips with RAS operation,” they write. “Decades of experience within the cage sector does not equate to competence in RAS operation. Equally, experience with operation of freshwater RAS farms, low biomass fingerling or smolt farms does not equip a manager to safely manage a marine RAS unit without significant risk.”

Other subjects covered by the study include:

- Energy requirements

- Solid waste disposal

- Fish welfare

- Potential for a market premium for RAS-grown fish

- Advances in technology

- Managing early maturation

- Thermal management

- Gas exchange

- Solids control

- Enhanced monitoring systems

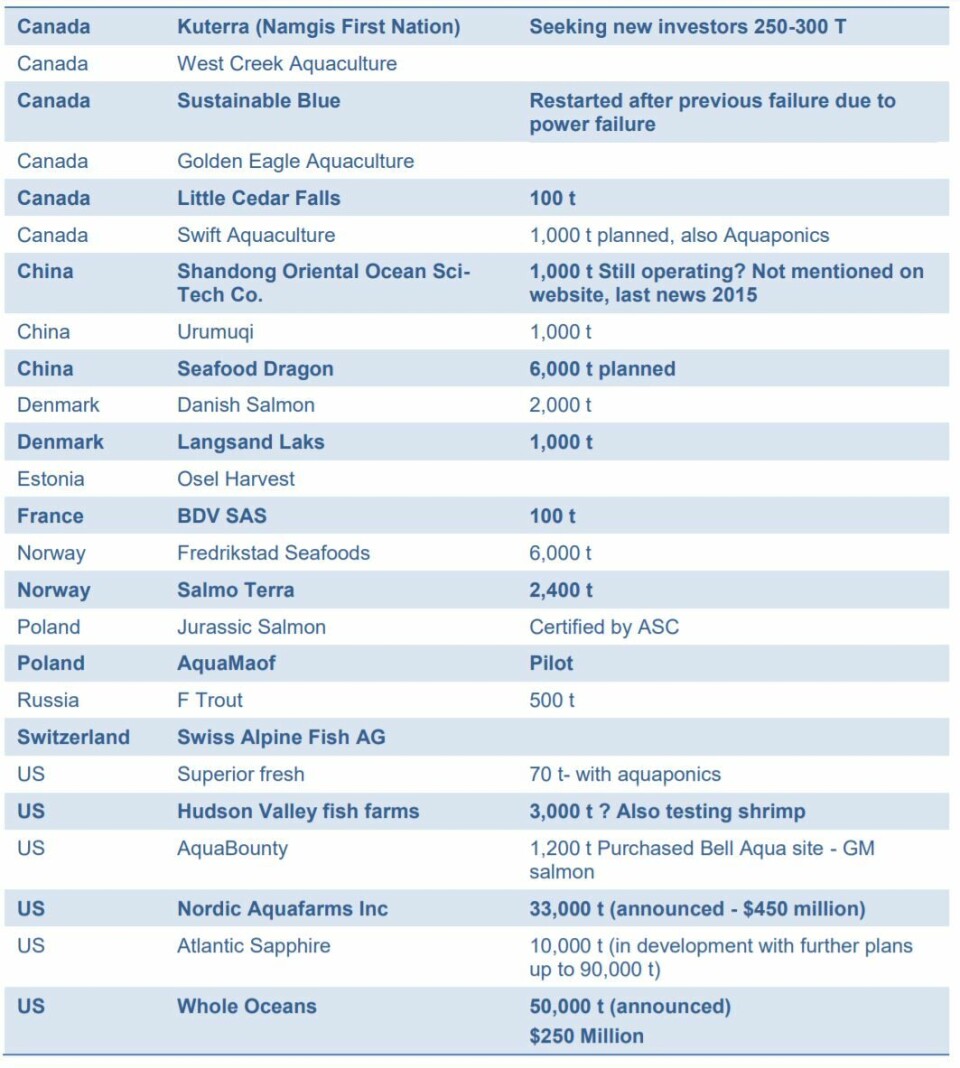

The authors conclude: “In research for this report we found 26 recent or proposed salmon RAS farms globally (Atlantic and Pacific salmon species). If all were developed and performed at design capacity, the production would be over 100,000 tonnes (3.2% of the global total).

“On these figures it is hard to conclude there is an immediate threat to cage-based salmon farming on purely commercial and economic grounds. However, economic factors can change and more importantly, social attitudes and policy changes could change and push the industry away from coastal cages.”

Both the update and the original 2014 report are available to download at the HIE website.