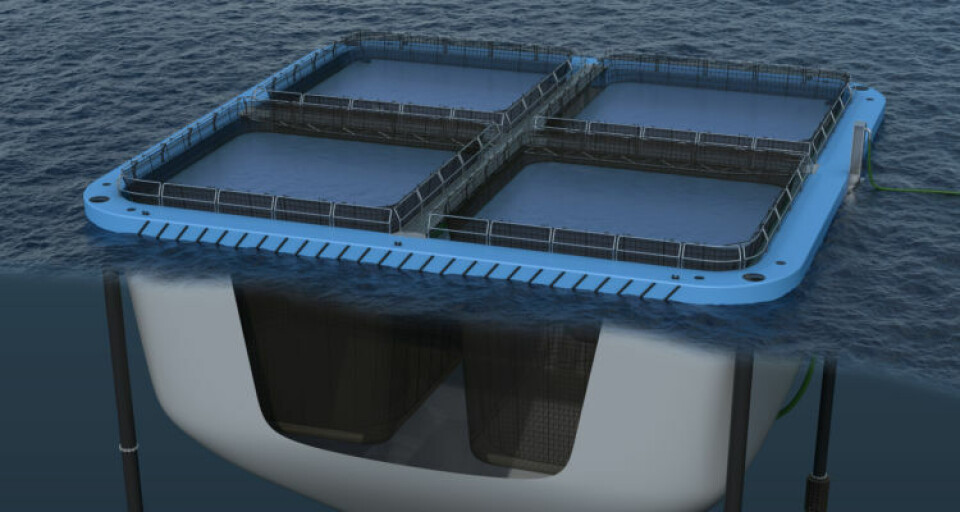

Broodfish / slaughter closed-cage concept unveiled

Norwegian company Ecomerden has developed a closed cage concept that, among other things, should keep lice out of slaughter cages.

“It is developed at the request of the industry,” entrepreneur Jan Erik Kyrkjebø told kyst.no.

Almost three years ago, the pilot of Ecomerden was put into operation for post-smolt production at Sulefisk. Since then, they have designed an updated commercial version of the closed cage, and have also designed a closed slaughter / broodfish cage.

"The technology of broodfish and slaughter cages differs somewhat, but construction of the cage is similar," explained Kyrkjebø.

He said the closed cage reduces the chances of infection from the slaughter fish to open cages, and also prevents lice infesting the slaughter fish. For the broodfish part, land use can be moved to sea.

Avoid emissions

"As the cage has four cages, it will contribute to easy sorting of fish [by size], and waste will be cleaned so as to avoid emissions at these pretty shallow sites," he said.

These cages have a different design and are square and not round like Ecomerden's post-smolt closed cage. Why?

"You do not have the need for the same currents for slaughter fish as you have for post-smolt, as the fish will only be here for a short period of time. In addition there is a simpler design more similar to steel cages that were mainly used before the rings,” he said.

Regarding Ecomerden’s post-smolt closed cage, Kyrkjebø said that it does away with problems of lice or escape.

“In addition, it offers a possibility of significant reduction in production costs over an entire generation. This obviously requires normal operation without illness and unforeseen events," he said.

99 per cent survival

He added that two years of testing had shown 99 per cent survival from 100 grams to one kilogram.

“There is no proof that the RAS facility is a better biological or more reliable solution than the production of post-smolts in Ecomerden. We can also clean seawater in and out,” he said.

Kyrkjebø believes the Norwegian government should consider granting exemptions for the production of post-smolts in closed cages in line with RAS on land up to one kilogram.

Ecomerden will be presenting the new cage at Aqua Nor in Trondheim next week.