Shetland grading panel maker casts its net wider

A Shetland company that makes an in-water size grader for salmon is extending its reach after signing a sales and distribution agreement with AKVA Chile.

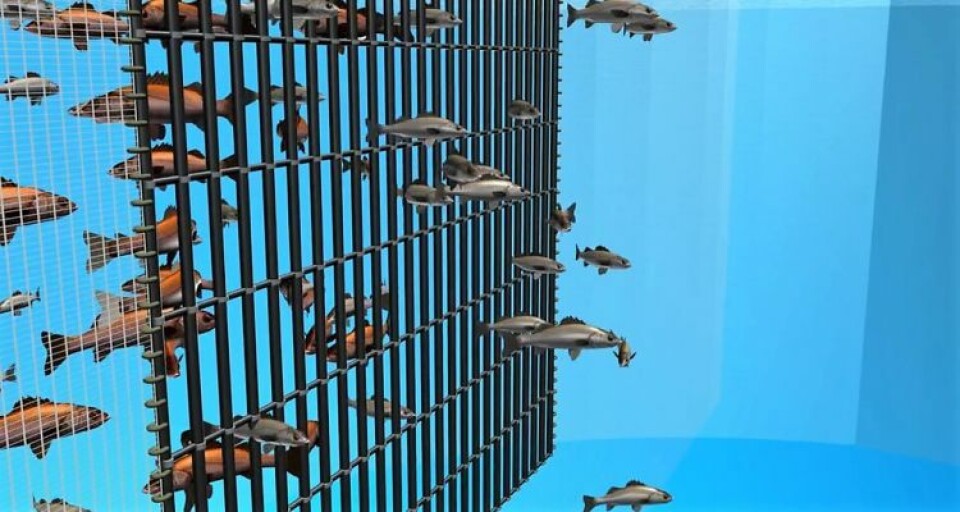

Grading Systems (UK) Ltd makes the Flexi-Panel, which the company says greatly improves fish farm productivity and efficiency by allowing farmers to select and harvest only high-value fish of optimum size, leaving smaller fish to continue their growth.

The company is 100 per cent owned by Norwegian company Viking Atlantic AS, which produces fish-sorters that have been used over the past 15 years, both in Norway and the rest of the world. Viking Atlantic chief executive Carsten Wangsmo says that he now wants to reach further out globally with the Flexi-Panel.

Wangsmo said: "We've found that the grid is becoming used more and more. Over the past three to four years we have noticed an explosion in growth and sold more and more."

Can be used on other fish

Marine Harvest are probably their biggest customer in Norway and Scotland, he said.

Wangsmo said that he wanted a more serious presence in the market, but it was challenging to reach out. He said there are opportunities for a large market for sorters, and that although today the Flexi-Panel is mostly used to the sort of salmon and trout, it can also be used on other fish.

"We now see that it is also used for other species, such as grouper, kingfish and yellowtail. The grill can also be used to remove wild fish and losers from the cage," he added.

The company claims the Flexi-Panel overcomes the problems associated with rigid grading grids which it says are heavy, damaging to fish and restrictive in terms of ‘grading area’.

Stress-free grading

Flexi-Panel’s lightweight, flexible construction allows very large areas to be easily and safely handled, allowing for quick and stress-free grading of large tonnages of fish, according to the company. The standard method is to install the Flexi-Panel into a sweep net, which is used to enclose all the fish in the cage. The sweep net is then gradually lifted, thus encouraging the smaller fish to swim through the openings in the Flexi-Panel, back into the cage.

Once the grading operation is complete (when all the smaller fish have swum through the openings in the Flexi-Panel), the farmer can either harvest the remaining larger fish directly from the sweep net or transfer them to another cage for harvesting at a later date.

No physical damage

Relatively short lengths of very rigid uPVC pipe are connected together using loops of a strong, abrasion-resistant twine to form the Flexi-Panel. The company says the plastic pipes are very smooth and are able to rotate, thereby completely eliminating physical damage and scale loss to the fish.

"Sorting works without the fish become stressed," said Wangsmo.

He added that the grid can also provide enhanced growth of smaller fish in the cage, and hypothetically lower cage feed conversion.

"The hypothesis is related to the fact that big fish prevent smaller fish from eating. So by slaughtering the big fish, the remaining fish grow to their optimum size."