Havfarm floated at Chinese shipyard

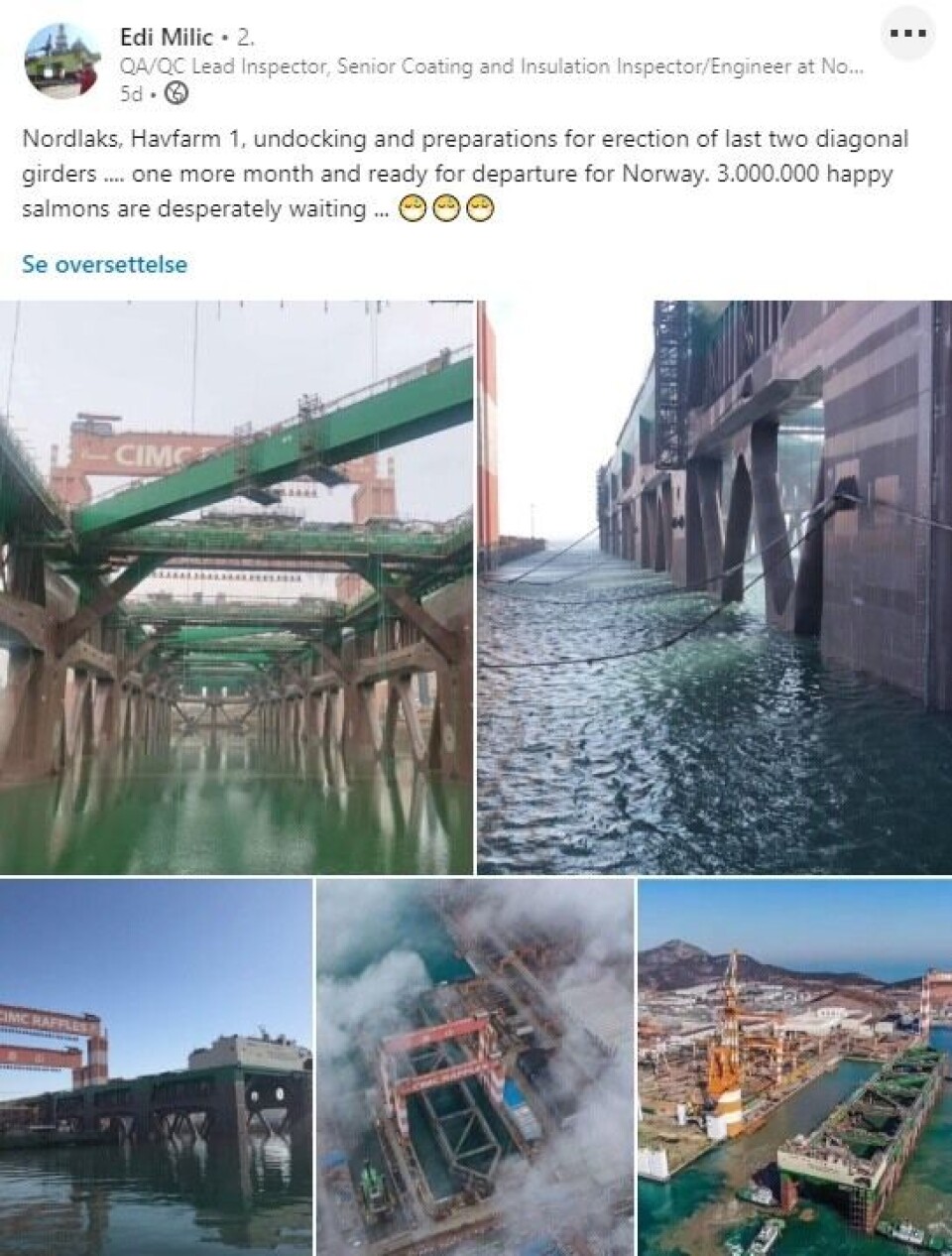

At the CIMC Raffles shipyard in Yantai, China the final mountings and adjustments are being made before the first Havfarm is shipped to Norway (See photo gallery below).

The Havfarms are part of Norwegian salmon farmer Nordlaks’ solution for sustainable development of the aquaculture industry.

On LinkedIn, Nordlax engineer and inspector Edi Milic, who is on site in China, writes that they are now working on the completion of the Havfarm.

3,000,000 salmon waiting

“Nordlaks, Havfarm 1, undocking and preparations of the last two diagonal girders …. one more month and it will be ready for departure for Norway. 3,000,000 happy salmon are desperately waiting,” writes Milic.

Nordlaks is one of the few companies that has been given a substantial number of development permits by Norway’s fisheries directorate, allowing it to grow more fish to offset development costs. It has been given 21 permits – equivalent to 16,380 tonnes of biomass – for its two Havfarms, one of which will be “stationary” (permanently anchored) and the other “dynamic” and designed to move between sites.

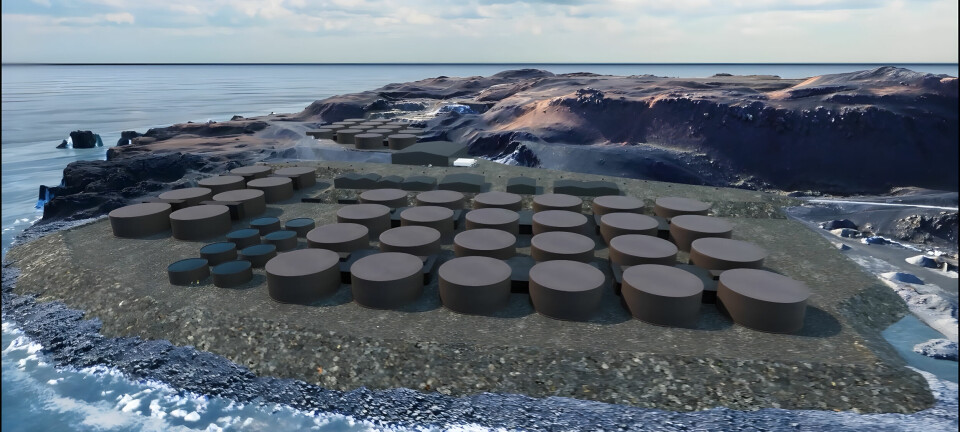

The first Havfarm, which is the stationary model, is planned to be located at a location south of Hadseløya in Hadsel municipality in Vesterålen, northern Norway.

The 385-metre long structure, named the Jostein Albert, has a capacity of 10,000 tonnes of biomass. It will be equipped with six nets of 47x47 metres, made of HDPE mixed with copper.

Swinging around the bow

The farm has an anchoring solution in the bow section, and will swing around the anchor point as determined by wind, wave and current direction. The mooring solution will depend on the location, and will be determined, among other things, by environmental loads, depth, bottom topography and composition.

The dynamic Havfarm will rely on dynamic positioning and propulsion systems to maintain position without mooring. Lighter anchoring solutions will be planned to relieve propulsion systems and reduce fuel consumption when the Havfarm is to be in the same location over time.

The dynamic Havfarm can thus be moved between areas depending on the season, weather and wind or other users’ interests.

Below: The Havfarm at Yantai. Photos: Edi Milic / LinkedIn.