£3m CO₂-to-aquafeed project kicks off

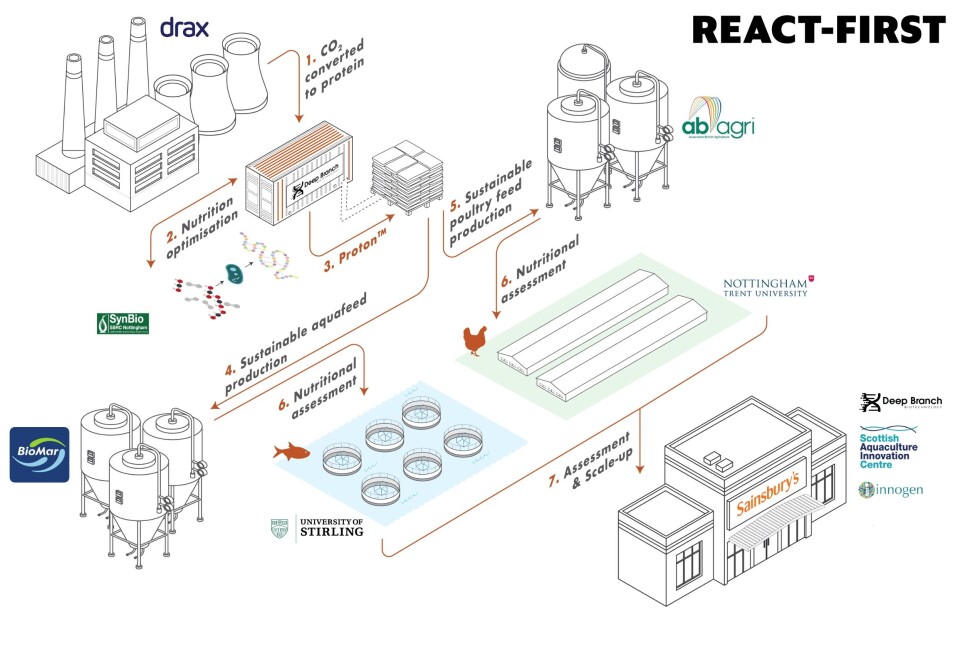

A carbon recycling project that uses CO₂ emissions from the UK’s largest power station to grow single cell protein (SCP) for use in fish and poultry feed has been launched.

REACT-FIRST is led by carbon recycling biotech company Deep Branch and the 10 project partners include aquafeed manufacturer BioMar, Stirling University’s Institute of Aquaculture (IoA) and the Scottish Aquaculture Innovation Centre (SAIC).

BioMar will produce feed with Deep Branch’s SCP, trade-marked Proton, and this will then be nutritionally assessed by the IoA.

Guidance from Sainsbury’s

Poultry feed will also be made with Proton by another REACT-FIRST partner, AB Agri, and assessed by experts at Nottingham Trent University’s School of Animal Rural and Environmental Sciences.

Retail chain Sainsbury’s will provide the project with market-focused guidance and assist with stakeholder engagement to ensure maximum potential market acceptance, penetration and value.

Deep Branch chief executive Peter Rowe said the company’s technology had “huge transformative potential”, but commercialisation was not possible without cooperation with key stakeholders throughout the value chain.

Critical data

“REACT-FIRST will obtain critical data about cost, digestibility, nutritional quality and carbon footprint of Proton,” said Rowe.

“Each of the project’s partners is playing an active role in the development of the process and generation of this critical data, harnessing their involvement and shared knowledge in the field of carbon emissions, the production supply chain, and ground-breaking biotechnology and technology, to create sustainable protein feed sources that will contribute to reducing the environmental impact of meat production systems.”

The project is being financed with £3 million from Innovate UK, part of UK government science-funding body UK Research and Innovation (UKRI).

Other partners are Drax, which operates the UK’s largest single site power station at Selby, North Yorkshire; the Synthetic Biology Research Centre at Nottingham University (SBRC Nottingham), a world-leading gas fermentation research group; and Edinburgh University’s Innogen Institute, an expert in value chain integration and responsible innovation.

A potential game-changer

BioMar salmon division vice president Paddy Campbell, said: “Aquaculture is expected to double production by 2050, however to achieve this we need feeds with minimal environmental impact.

“The REACT-FIRST project is the first step towards the commercial development of a new potentially game-changing protein source, Proton, using new technology to capture waste CO2 and creating high-value sustainable protein suitable for the aquaculture industry.

“At BioMar we are constantly seeking innovative raw materials that don’t compete with human food production and nutrients from by-products that minimise waste. We are excited to be part of this project to see how Proton will perform in aquaculture feed.”

Nutritionally optimised

IoA scientist Monica Betancor is leading the study into the feasibility of SCP as a substitute for marine and terrestrial meal in salmon feeds.

Betancor said the UK salmon industry is expected to increase significantly, but that such growth can only be achieved in a sustainable manner by replacing the traditionally used marine ingredients in aquafeeds – fish meal and fish oil – with more sustainable options.

“The main alternative to fish meal in aquafeeds is vegetable meal, however, this has its constraints, and single-cell protein is an excellent alternative as it is nutritionally optimised to meet the demands of aquaculture,” explained the researcher.

“Our work in the REACT-FIRST project will determine its feasibility as a substitute for other protein sources in the feeds for farmed salmon.”

75% smaller footprint

Judith Batchelar, director of Sainsbury’s Brand, said REACT-FIRST’s focus aligned with the retailer’s recent pledge to become “net zero” across its own operations by 2040.

“Being part of the REACT-FIRST consortium is an outstanding opportunity to produce feeds for our farmed fish and chicken, with 65%-75% smaller carbon footprints than existing feeds, no requirements for arable land, minimal water usage, and so we build more resilience into our supply chains for animal feed,” explained Batchelar.

“REACT-FIRST should help the aquaculture and poultry feed industries move towards self-sufficiency from a dietary protein perspective and reduce the instability of animal feed prices experienced by farmers.”

Flue gases

Deep Branch, a spinout from Nottingham University, has a pilot plant within Drax power station’s Carbon Capture Usage and Storage (CCUS) Incubation Area. It extracts flue gases from the power station’s renewable electricity generation to feed to microbes, which can make SCP.

In June last year, Drax was capturing a tonne of carbon dioxide a day from its C-Capture BECCS pilot, but once scaled up it could be capturing up to 16 million tonnes of carbon a year from its four biomass generating units.