UK to host fishmeal replacement facility

A Californian firm has announced that it aims to produce the “gold standard fishmeal replacement” for the aquafeed industry from a new facility in Teeside.

Located at the Centre for Process Innovation (CPI), Teesside, Calysta will develop the production process for FeedKind, a high protein microbial ingredient that aims to reduce the aquaculture industry’s use of fishmeal. It is produced using a natural fermentation process by organisms that use methane as their source of energy. Billed as “natural, safe and non-GMO”, it is approved for sale in the European Union.

The decision to base production in England follows on from a conditional award of up to £2.8 million by the Exceptional Regional Growth Fund (eRGF), subject to due diligence from the UK Government. This will contribute to a £30 million first phase investment over ten years by Calysta to develop a Market Introduction Facility to undertake R&D critical to commercialise FeedKind and develop the technology for other applications.

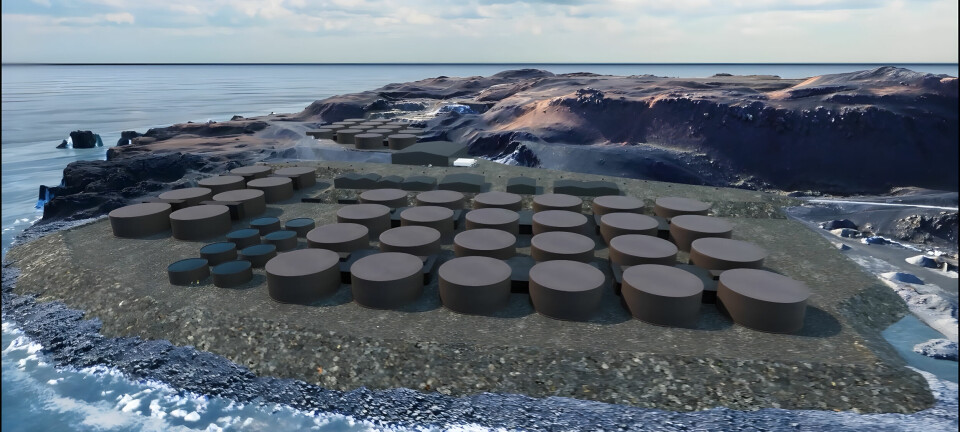

Calysta plans to locate a novel loop reactor adjacent to CPI’s existing National Industrial Biotechnology Facility. This loop reactor will incorporate Calysta’s proprietary, best-in-class gas fermentation technology. CPI staff will then gain experience in operating the facility under Calysta’s supervision

Alan Shaw, Calysta President and CEO, explained the company’s plans to Fish Farming Expert:

Are you focusing primarily on the salmon feed industry, or looking at other species too?

The production of the single cell protein was first developed in Norway in the 1980s and we had the option of establishing the plant in Norway – the closer we get to the salmon farming industry the better – but North East England is a great place for developing the facility and close enough to the salmon industry in both the UK and Norway.

At least one of the big four feed producers used the product in their feeds in the 1990s. But we’ll be looking to expand into other industries such as tilapia, pigs and chickens over time.

Would you consider selling finished feeds or would you sell FeedKind to established feed producers?

We would rather concentrate on investing in new R&D – FeedKind will be a whole family of products and we already have the base protein. The great thing is that it contains no chemicals, no volatiles, is very clean and could almost be classified as organic. It is also a great product for food security, as it’s not taking anything out of the food chain.

Do you have any idea about the relative pricing of FeedKind vs fishmeal?

The initial project, which had its roots in Norway in the 1980s, was closed down in 2006 because of high natural gas prices and low fishmeal prices. Recently, however, fishmeal prices have been rising by around 7.5 to 8% per year while FeedKind is produced using methane, the price of which has fallen dramatically, especially in the US in recent times, which means it will be cheaper to produce than fishmeal.

How long before it’s commercially available?

This is a market introduction facility and we aim to be able to produce samples before the end of the year and it will then be up to the feed producers to decide what inclusion rates they want for the product.

We’ve done considerable market research and extensive interactions with feed producers and have a 2-5 year commercialisation strategy for the product and we’re very serious about getting the product to become the gold standard of the industry, while the feed industry has unanimously said that they’ll use the product.

Will FeedKind include the long chain fatty acids EHA and DPA?

While it’s a near-perfect match with fishmeal and, like fishmeal, contains about 10% fat, it does not contain the key omega-3s that are found in fish oil. We would, however, like to develop a product that contains both proteins and omega-3s.