Salmon farmer saving planet and cash with hybrid power

Scottish Sea Farms has reported “fantastic” results from a bespoke hybrid power system aboard one of its feed barges, dramatically reducing fuel consumption, carbon emissions and operating costs.

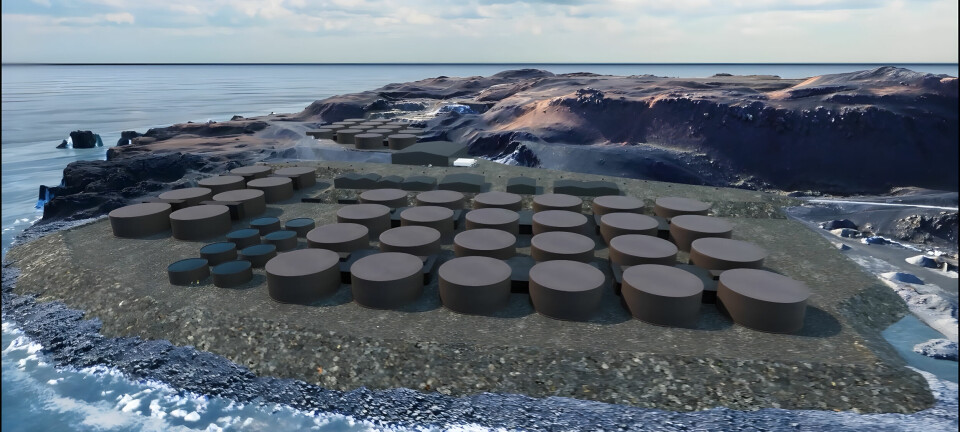

The pilot initiative, at the company’s Spelve farm on Mull, is part of SSF’s drive to make its activities more sustainable and contribute to the Scottish Government’s ambition to be net zero by 2045.

After just four months of operation the system has achieved both cost savings as well as environmental benefits, Spelve farm manager Alan Tangny said in a press release.

Fuel lasting longer

“We used to be filling our diesel tank at least once a week and now we’re probably getting four times longer between fills,” said Tangny.

Designed, built and monitored by Aqua Power Technologies, the hybrid concept has been shown to offset 32,408kg in carbon since the pilot began in September, comparable to the weight of a standard fuel road tanker of 32,000 litres.

Contained within a 2 metre-long cabinet, the hybrid system includes 24 batteries and a control panel. It works alongside the conventional diesel generator, intelligently monitoring the power demand and seamlessly switching between generator power and battery power.

Logging systems

At times of greater demand, during feeding for example, power is handed back to the diesel generator which simultaneously charges the hybrid’s batteries.

During lower demand, the hybrid takes over, remaining on 24/7 to power comparatively low loads such as environmental logging systems and lights.

Power profiles

Aqua Power founder Sam Etherington said the technology has been in existence for 20 years and is typically used in cars, underground trains and off-grid homes.

But it had not been deployed on a salmon farm until he approached SSF with his novel adaptation for the sector.

After Spelve was identified as a suitable site for the trial, Etherington’s team installed monitoring equipment for two weeks to gather data on power profiles and trends at the farm.

Smaller footprint

The information was then analysed to understand the reductions in carbon production and diesel use achievable by integrating a hybrid system, before a bespoke specification was proposed.

“The hybrid system can be remotely configured farm by farm, according to power needs, to yield the highest savings,” said Etherington. “At Spelve, it’s currently configured to take over with anything less than 10kW, which covers everything except the feed blowers.

“The peak feeding times are between 10.30am and 2.30pm so during all those other hours before and after, the hybrid maintains power to the farm, enabling savings to be made.”

£18k-a-year fuel saving

The total annual carbon offset is estimated at 79,400kg, and the annual net saving in diesel costs, based on today’s price, is around £18,000.

Aqua Power Technologies has an online data platform, AquaStat Internet of Things (IoT), that allows farmers to log on and track real time information, including the amount of carbon and diesel offset and the return on investment.

SSF is also trialling LED lights on Spelve’s pens in place of traditional metal halide lamps. These, said Tangny, are much lighter, brighter and use less power.

Less power, more light

“These are only 100W lights yet they produce more luminance than the 400W metal halide lights. They require a lot less power, so the diesel saving has been phenomenal, especially combined with the hybrid as well.

“We would have had the generator running 24 hours a day to power the lights but these LEDs run off the battery pack, no problem.

“We have observed no difference in fish behaviour, growth or maturation using LED lights instead of metal halide lamps. We can still maintain high levels of fish welfare whilst reducing our carbon footprint and saving money at the same time.”

Benefits of monitoring

The real-time monitoring platform has given SSF scope to make even more improvements to the farm’s power use, said SSF environment manager Sheena Gallie.

“This level of monitoring of our power use is something we wouldn’t have had otherwise. Aside from the direct benefits, there are a lot of other things we can learn,” said Gallie.

“Off the back of the success of the Spelve system, we will be looking to work with Aqua Power Technologies to identify other farms where energy use profiles would indicate its suitability. There is a clear opportunity for the company to reduce its reliance on fossil fuels and, in doing so, significantly reduce carbon emissions.”