Converting super trawler

- The ship will become a Life Science Factory that is unmatched in the biomarine industry, says Aker BioMarine President and CEO Helge Midttun. The ship`s crew will conduct research and development in modern facilities and operate an advanced processing plant for high-value krill meal brand named Qrill and primary production of krill oil. Processing efficiency and quality are enhanced through careful raw materials handling, reduced energy consumption, and maximum retention of health-promoting bioactive ingredients. The processing plant`s technologies enable production of significantly greater tonnages of krill meal and krill oil from the live krill delivered by the ship`s Eco-Harvest continuous trawl harvesting system.

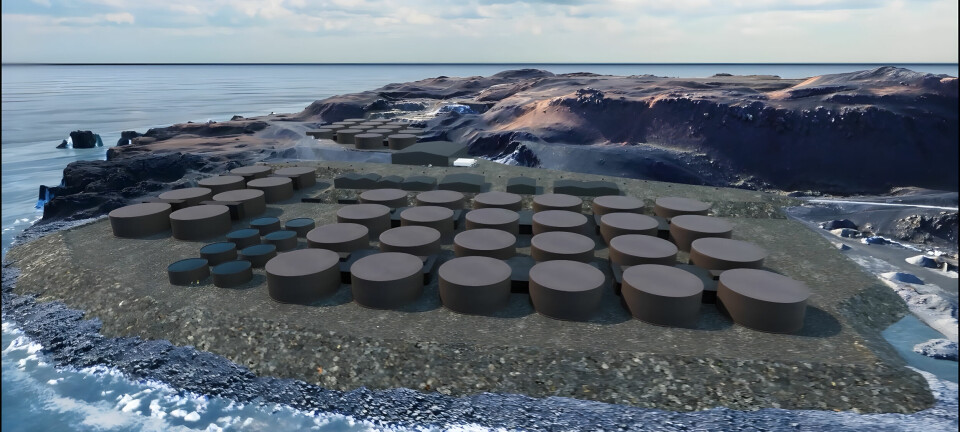

An advanced krill harvesting and processing ship brings us much closer to becoming an internationally leading marine biotechnology company. Aker BioMarine possesses a unique, environmentally friendly harvesting technology. We are refining our processing technology and increasing production at our own facilities. Qrill is already well established in the aquaculture market. In the first quarter of 2008, we will introduce our own brand name dietary supplement product for nutraceutical, functional foods, and other health-related markets,` says Midttun. Today, production takes place using Aker BioMarine`s factory trawler Saga Sea. In January 2009, the Atlantic Navigator will also enter krill operations, after conversion at the Victor Lenac shipyard in Croatia. The extensive rebuild into a Life Science Factory will cost approximately NOK 340 million. During conversion, the factory ship`s hull will be lengthened by 25 meters to a total length of 121 meters. When commissioned, the vessel will be renamed Antarctic Navigator. Aker BioMarine`s new krill vessel will have an annual production capacity of 12,000 metric tons of Qrill. As of 2009, Aker BioMarine`s total production of krill meal will be approximately 20,000 metric tons. New technology for boiling will increase the proportion of the harvest that can be processed into first-class krill meal. The new boiling process will extract and preserve a larger proportion of the krill`s bioactive components, which significantly increases the value of the krill meal. Although, primary production will take place on- board the factory ship, final production of krill oil will take place onshore. Research and test production will also be performed onboard.

Aker BioMarine has developed a dietary supplement product from krill oil that contains high concentrations of phospholipids, Omega-3, and the antioxidant astaxanthin. Studies show that these bioactive ingredients contribute to improved cardiovascular, heart, brain, and joint health, and reduce inflammation. The dietary supplement will be launched under its own brand name in March 2008. Aker BioMarine has conducted extraction of krill oil from meal at onshore facilities for several months. Industrial test production has shown excellent product quality, volumes, and suitability for target markets. `The combination of our two modern vessels and industrial end-production of krill oil onshore ensures an optimal value chain spanning from harvesting to deliveries of high-value ingredients that we produce and market under our own brand names,` says Midttun.