High hopes for cutting-edge halibut scheme

Norway’s largest halibut producer Sogn Aqua is making good progress as it seeks to set up the infrastructure that will allow it achieve 800 tonnes of production a year, aided in part by Sogn Aqua Juveniles.

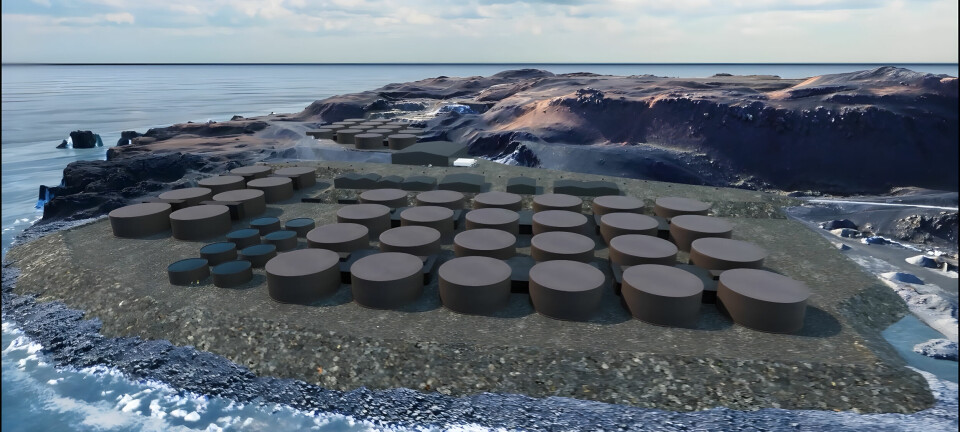

“Our new facility in Ortnevik is well underway – about 6000m2 is already built and in use, while it will be increased to 10,000m2 by the summer,” Jan Arne Brekke, Sogn Aqua’s CEO, told kyst.no.

He notes that there is still some fine-tuning needed at the new facility, but it’s working well, despite being three times larger than the company’s previous site – thanks in part to prior research.

“Sintef has helped by simulating flow velocities in canals and pools [prior to the construction of the facility?],” he says.

According to Brekke, the company has installed about 3km of new pipes to obtain their water from a depth of 100m in the fjord. And, like the previous plant in Slantevika, the company has adopted recyclable materials. The Slantevika facility will now be converted into hatcheries, raising the fish from 5 grams to 200 grams before transferring them to Ortnevik, while another company, Sogn Aqua Juveniles, will concentrate on the early phases of production.

Their current aim is to increase output from 50 to 800 tonnes a year, and the company – which now employs 10 people – is in the process of establishing offices in Bergen for sales.

Juvenile expansion

Meanwhile, Sogn Aqua Juveniles – an independant company, but one which works closely with Sogn Aqua and has produced juvenile halibut for about a year now – is currently looking to set up a broodstock plant.

“We are now considering building our own broodstock facilities beside the hatchery to ensure a concentrated and compact construction,” says CEO of the company, Rune Valaker.

However, they will first assess the results of a smaller scale pilot plant.

“The purpose of the pilot project – which was established in October 2015 and will run until December – is to map the technology we will use. Decisions will be based on the experience gained there,” he says.

“In 2016 we produced approximately 10,000 fry, but for 2017 we aim for 40,000,” he adds.

Production is dependent on a decent ova supply, but Valaker says that last year largely went well. “Production decreased slightly – we had some incidents but we know where we went wrong, but we also had a very productive round in the autumn, and the use of new technology has been very promising,” he says.

It is often in the early life stages of halibut that high mortality, poor growth and first feeding problems arise, as a result of difficulties with pigmentation, eye migration and poor growth in male fish. All-female production avoids the problem of poor growth in male fish, but Valaker says they will continue to produce both males and females for the time being.

“We want to have a better understanding of the more fundamental issues before we proceed with an all-female policy,” he explains.

“Eye migration and pigmentation have been the main problem related to quality, and this is where I argue that the quality of what we have produced is exceptional,” he says.

The quality is, according Valaker, a result of the feeding regime, which was instigated with the help of representatives of C-feed and Sintef, and now includes the use of copepods at some stages.

“We provide copepods the first few days, then Artemia, followed by an extra dose of copepods before the initial dry feed,” he says.

In addition, he explains that algae, which is used to feed the copepods, also makes it easier for the young fish to identify their prey. He adds that it is essential to grade out all but the best quality fish as early as possible.