Halo promises cheaper, gentler cage cleaning

Having built up Akva Group - the largest technology supplier to the international aquaculture industry - the Molaug family are once again at the forefront of innovation, this time with a small rail robot that cleans nets and make life better for the fish.

"We have been working on this for four years. In 2014 we initiated cooperation with Bremnes Seashore, and since then it has developed rapidly," founder and investor Knut Molaug told Norwegian Fisheries / kyst.no.

He has worked with technology to the aquaculture industry since 1983 when he went into his father's firm, Akva. For many in the industry, he is best known from his time with Akva group where he was CEO until 2010. But now it's all about the net cleaner. And it's Anders Molaug who has accounted for much of the technical development of the new product. He is also director of development of Aqua Robotics, where Ole Molaug (his father) is a shareholder together with his sons Knut and Anders. The company has a healthy NOK 10 million in new equity.

After four years of trial, modification, tests and changes, they finally have a product that they are happy to launch on to the market.

"It's taken four prototypes, much hard work and many versions before we arrived at the solution which has been undergoing testing since late summer 2016 with Bremnes Seashore. Therefore, it is with a good dose of pride we launch HALO Net Maintenance System at AquaNor fair in August," says Knut Molaug.

Norwegian Fisheries / kyst.no visited as they made the final refinements before the product launch.

What's so revolutionary about the Halo net cleaner?

"It is gentle, it is efficient and it is less expensive than traditional net washing," says Knut Molaug.

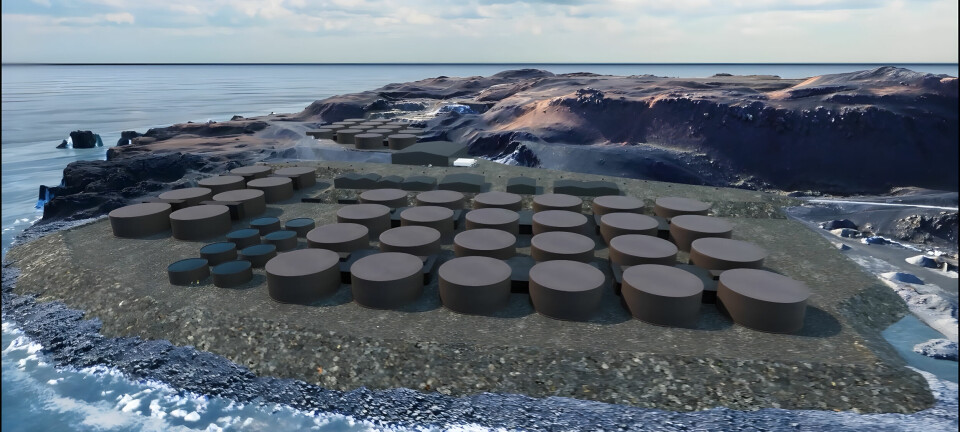

In simple terms HALO Net Maintenance System is a patented, fully automatic robotic system mounted in each cage, and which in turn keeps the net clean by a rolling brush unit automatically moved up and down along the net. Using reversible wings / foils the brush is pressed close to the net wall. The robot unit moves automatically around the cage so that the whole cage is cleaned daily from top to bottom.

"How often you want to clean the net is up to the individual user. HALO can go once or many times a week or a day. The point is that the result should be always clean," says Anders Molaug.

Better and cheaper

Knut Molaug quickly reviews his calculations of using their HALO robot compared to traditional flushing.

"I've done some research in the market, especially in terms of what a farmer would pay for a net cleaner and not least how many net washes happen during the year," says Knut Molaug.

His conclusion is that a net-cleaning using traditional flushing costs NOK 30,000 per cage. The number of flushing treatments required throughout the year varies with geography and seasons, but the average may be around 20-22 treatments per year per cage. It will then give annual costs of NOK 600,000 to 700,000 (£67,000) annually per cage.

"With our HALO cleaner, the investment cost will be NOK 200,000 (£19,000) per cage. It includes equipment and installation. Then it will cost NOK 30,000 (£2,900) per month in rent. This means that we take responsibility for the operation and support," explains Molaug.

Better environment

Development manager at Bremnes Seashore, Geir Magne Knutsen emphasises environmental benefits achieved with HALO-cleaner from Aqua Robotics.

"We avoid using copper impregnation, and we can clean continuously, which in turn means optimum throughput in the cage," he says. He also emphasises the fact that high-pressure flushing and less-frequent cleaning cause more fouling and when flushing occurs there is often a "cloud" of particles that are not good for the salmons' gills.

"I firmly believe that this has a negative effect, but it is obviously difficult to measure in the short term," says the biologist, who has 15 years' experience as a production manager at Bremnes Seashore.

"Our owners have a very clear understanding that Bremnes Seashore will be at the forefront when it comes to quality and sustainability. If we can avoid using copper while the fish get better conditions in cages, this is something for us," he says.

Knutsen describes the concept of Aqua Robotics is interesting so far.

"To remove fouling before it has time to attach itself is a simple principle. Nets are washed or brushed several times per day and are therefore always clean. This means that the fish always have optimal growth conditions. We look forward to seeing the further results to come," he says.

Just the beginning

A robot-controlled brush about going up and down the net wall can also be equipped with a camera and do the job as primary net inspector. Each square centimeter of the net wall is in practice inspected.

"We also see other features this can have, including measuring oxygen and temperature. Moreover, it is important to have a visual contact with what happens in the cage," explains Anders Molaug.

Among other things, farmers can see that the dead fish collector works and observe the general behaviour of the fish.

Knut Molaug has examined the market potential and concludes by saying that there are about 4,000 cages in Norway and the same in the other parts of the salmon-producing world.

"This will be exciting," he says.