A burning desire to deal with waste

A new farm design that incorporates novel ways to utilise fish waste has been revealed.

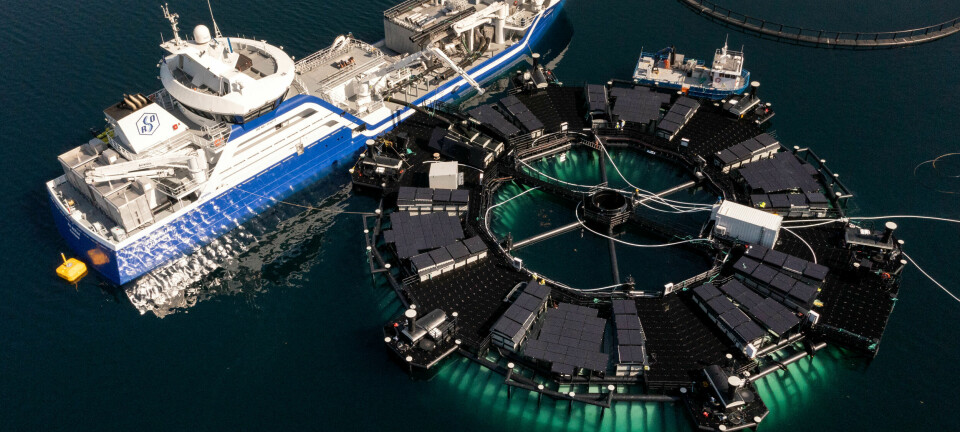

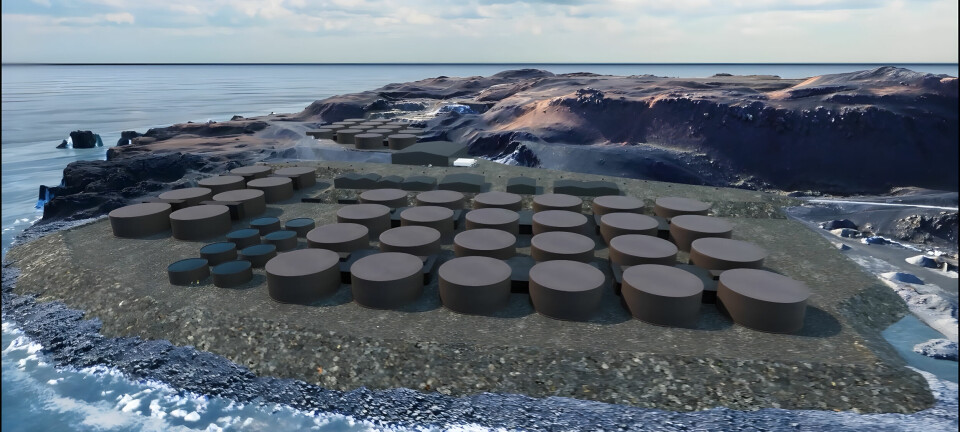

Called the Green Fish Farming concept, it is the brainchild of CMR Prototech researcher Crina Silvia Ilea. The company has delivered solutions to the International Space Station (ISS), but now wants to shift its focus to the challenges posed by the new generation of closed fish farming facilities – of both onshore and marine varieties.

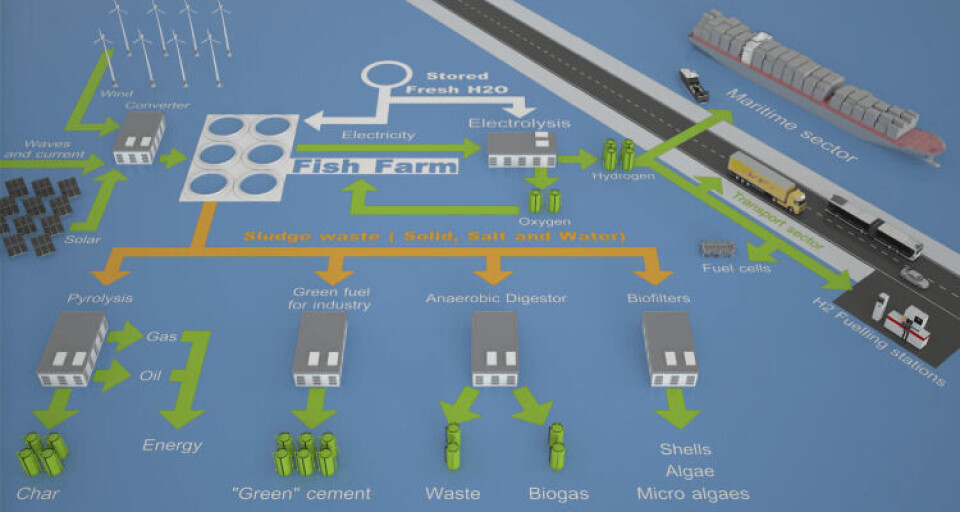

Ilea’s idea addresses the challenges posed by sludge production and oxygen and energy demand in closed farming systems. The concept comes with four different options, depending on whether your system uses fresh water or sea water, and on which renewable energy sources are most suitable.

“The end product will be a zero-emissions farm,” Ilea explains to kyst.no.

The idea came after she examined various closed facilities – many of which are currently being planned as part of the current development licence initiative in Norway – and realized that many had not thought about what to do with the sludge.

“Then we made a few calculations as part of a pilot project, and found that some marine sites emit more sludge than the entire city of Bergen,” she says.

Prototech also found out that the volumes were too large to be processed in the local biogas facilities.

Bernt offerings

“The local biogas plant in Rådalen does not have the capacity for what's produced by a single farm. One alternative solution is to use as a process called pyrolysis, in which sludge is burned to create energy,” says the CEO of CMR Prototech, Bernt Skeie.

“Pyrolysis is in practice the same process that happens when you clean the oven with high heat,” he adds.

“Theoretical research into using fish sludge in such reactors suggests they are able to provide up to three times more energy than other alternative technologies,” says Ilea.

“However, the reactor is not yet built or tested. It is now our first priority,” stresses Skeie.

Sludge from fish farms can have high levels of salt, which ruin biogas production – another reason why pyrolysis is a better alternative. Now they want to build a prototype of a pyrolysis reactor extracting valuable phosphorus before the sludge is burned.

The concept also envisages using electrolysis to produce hydrogen and oxygen on site.

“The electrolysis plant from NEL [a Norwegian company specialising in hydrogen production] is the size of a container and provides enough hydrogen to power a small fleet of boats,” says the Prototech boss.

Such electrolysis plants require little power, as Skeie explains, and this could come from wave, wind and solar power.

“By integrating electrolysis into the facility, hydrogen can be used for the company’s boats and the oxygen can be used in the water,” says Ilea, adding that it is also possible to sell the hydrogen.

According to her calculations it’s cheaper to buy an electrolysis machine, than buying a year’s worth of oxygen, so it's a good business option.

Skeie and Ilea say they are thinking big and will put in place a partner who can go from pilot scale to industrial scale. They add that they have already received an offer to build a model plant from a large international company but he’s now looking for a Norwegian aquaculture company to sign up too.