Design and dimensioning of land based sites for the production of post smolt

Børge Søraas (1), Idar Schei (1), Rune Eriksen (1) (1)AquaOptima AS, Trondheim

Introduction The land based production of post smolt up to 1 kg has lately become a production strategy of interest. In the operations regulations one allows for the production of post smolt up to 1 kg, subject to certain requirements. The reason for this increase in interest for onshore production is to be found in several commercial and administrative advantages:

From both the administrative and commercial point of view one expects that this type of production will give advantages when it comes to e.g. the environmental aspect, one of which is sludge collection. One also expects that land based production of post smolt will result in advantages for fish health and fish welfare.

Reports on losses from aquaculture in cages show that about 20% of the fish put out does not reach harvest size. Most of these losses, disease outbreaks and sea lice infestations happen on small fish. The launching of 1 kg salmon will result in a number of advantages when compared to the current launching of 60 – 250 g smolt. When keeping the fish onshore until they have reached 1 kg, one will reduce the growth period in cages up until harvesting down to 10-11 months instead of today’s 16-22 months. This again reduces the time of exposure for sea lice, virus and bacterial disease. A reduced production time at sea will also reduce the risk of escaping and facilitate a number of costly and risky operations, such as no need for net changes during the cage phase, no sorting and no/reduced treatment for sea lice. Other obvious advantages with such a production strategy are a better MTB utilization through increased production per site and an increased flexibility w.r.t. zones.

Case: 1million 1 kg/year In this case we will look at a land based recirculation system which is to produce 1 million salmon of 1 kg per year. The work with designing and dimensioning a land based recirculation system will normally be split into three phases. The first phase consists of setting up a production plan. Important inputs here are temperature and growth factors. The second phase will be to set up the logistics and layout of the site which is appropriate w.r.t. the user’s stocking plans and farming mechanics (?). This phase requires good communication between the user and the equipment supplier. The third phase will consist of dimensioning of the water treatment system, based on the conclusions reached during the first two phases.

Design and dimensioning Fact box: Step 1: Production plan, growth based on Skretting table 2012 Step 2: Lay-out, number and size of tanks, number of units, movement of fish Step 3: Dimensioning of water treatment system, based on maximal feeding and water quality criteria TAN<1.5mg/l CO2<15 mg/l Water replacement: 10-20% per day

Production plan A prerequisite for the production plan in this case is set at a temperature of 12-14 °C. It will be advantageous with a moderately high temperature in order to ensure a relatively rapid turnover of cohorts. At the same time, it is important not to have too high temperatures, in order to avoid compromises with parameters such as oxygen requirements, CO2-concentration in the water and fish health. The use of possible waste heat will be economically advantageous, but not all localities have access to this. For most localities it will be advantageous to take in deep water, possibly from two different depths in order to exploit natural temperature variations. By using water from the deep, one will achieve a more constant need for heating from the heating source plus the biological advantages that follow with a more stable water quality, few algae, fewer pathogenic bacteria and parasites.

Layout Once the production plan is determined this forms the basis for calculating tank sizes, number of tanks and the rest of the layout. In this case we have chosen 6 tanks of 750 m3 each. The reason for this is to have units of such a size that one achieves economic advantages of big operations and reduce investment costs per m3 farming volume, but at the same time to have enough tanks for proper sorting and movement of fish in the site. We suppose smoltified fish of 55 g put in 2 tanks of 750 m3. After 13 weeks sorting and splitting of the fish into 3 tanks is required. The fish will then have reached an average weight of 300g. After 18 weeks the fish will have to be split into 4 tanks in order to avoid over-population. If one wishes, the fish can be sorted at this stage. The fish will then be kept in 4 tanks until they are launched in netpens. After 24 weeks in a land based system, the fish will reach an average weight of 1 kg and they will be ready for launching in pens. Some farmers will sort the fish from well boats and into pens in connection with transport to the pens.

Fact box: Production plan and layout 12°C constant temperature, 55g – 1 kg in 24 weeks 4 cohorts each year 261500 fish, 55 gram per cohort (5% mortality) 6 tanks of 750 m3 each 2 tanks from 55gram to 300 gram, 12 weeks 4 tanks from 300 gram to 1 kg, 12 weeks Max. density: 72 kg/m3 Max. feeding: 3637 kg/d

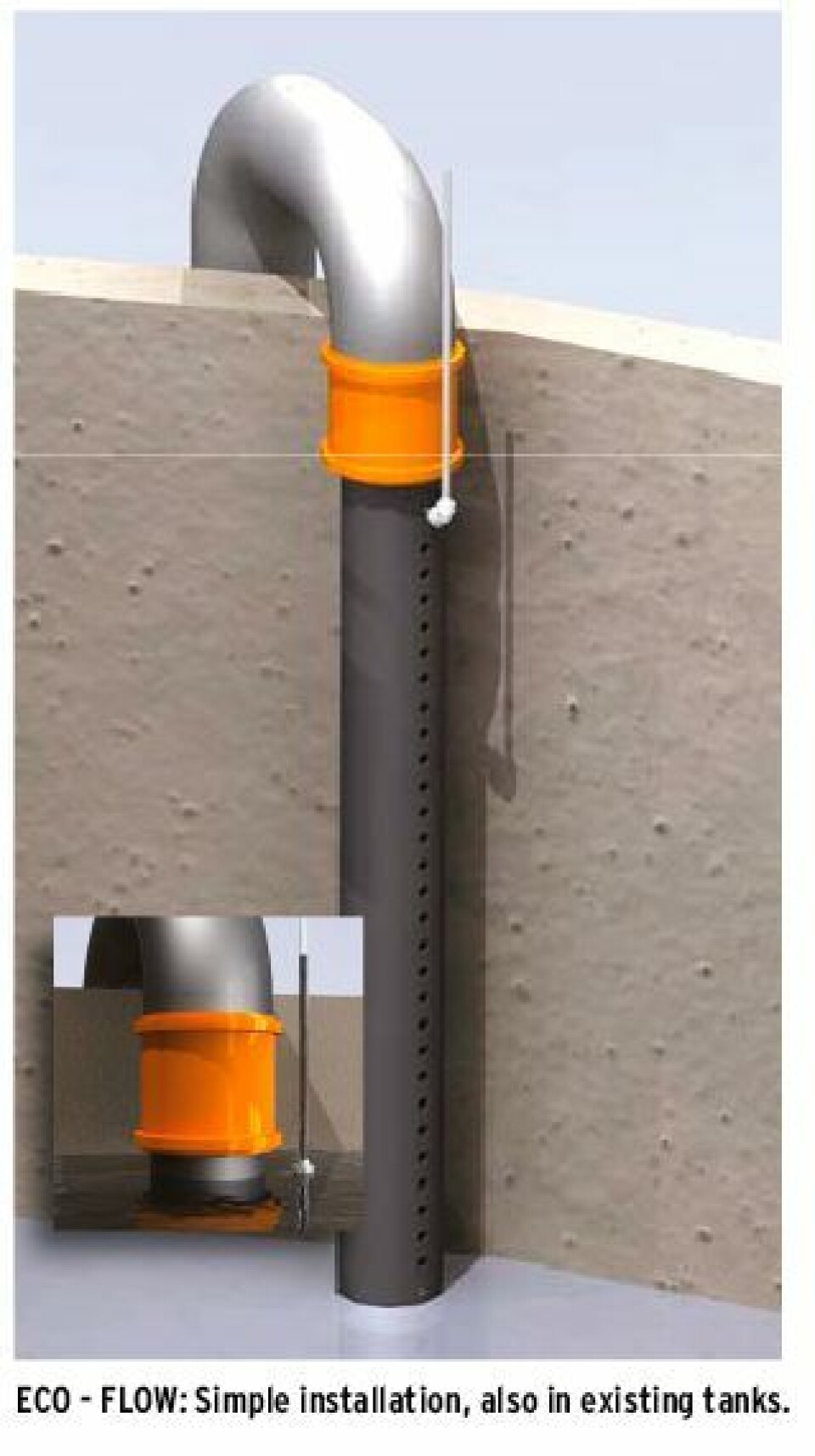

Dimensioning and water treatment system When dimensioning the water treatment, one has to take into account three main processes: A) Removal of particles, B) transformation of ammonium to nitrite (nitrification), C) CO2 removal. With big tanks like the ones here one requires a stage of pumping, where the water goes to particle removal, nitrification and CO2-removal by gravitation. The pumps are placed under the ripplefilter (?) and they pump the water back to the fish tanks.

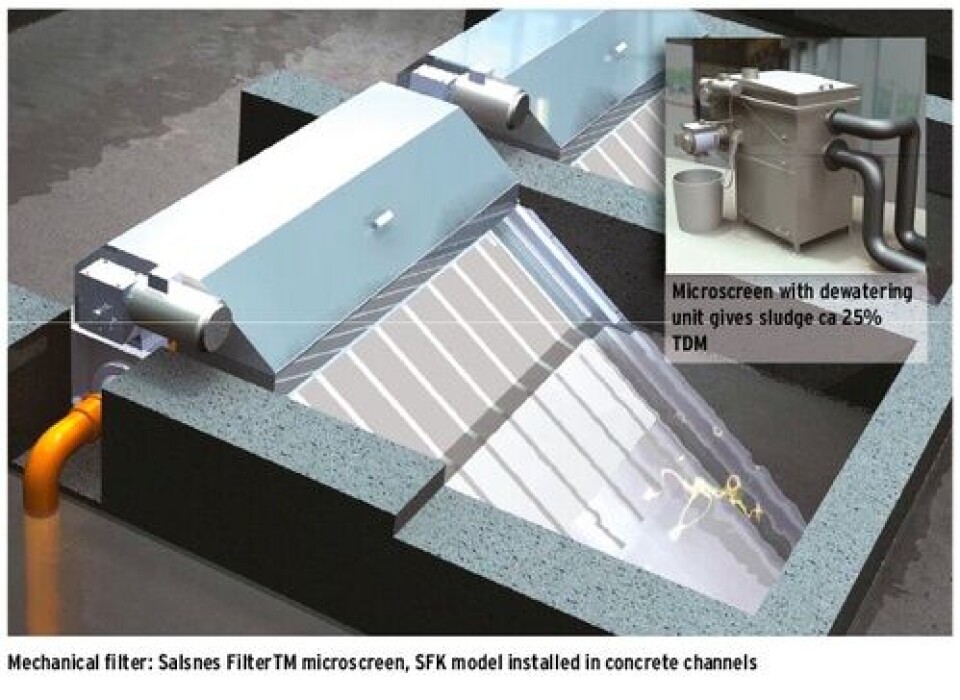

In the AquaOptima design the particle removal will already start at the tank-level. Each tank is equipped with particle traps and sludge collectors. 50% of the suspended matter in a recirculation system is removed with this patented particle removal system and it takes less than 5 minutes from when the particles get sedimented on the bottom of the tanks until they go into the particle trap and on to a sludge collector on the outside of the tank. By taking out such a big proportion of the particles at this stage, one can get big savings during further water treatment because the following water treatment components can be scaled down. For further removal of small particles a Salsnes beltfilter is often chosen.

After particle removal the water will continue to the Biofilter for the conversion of ammonium. During recent years AquaOptima has co-operated with Krüger Kaldnes for the use of the patented MBBR system as a biofilter. This usually consists of two chambers and it is filled with a biomedium that has a big surface area. The dimensioning of the biofilter is done by calculating the required area of the biomedium based on the bacteria’s capability to convert ammonium to nitrate. One can find data on these conversion speeds in published research articles. The bacteria’s capability of decomposition of ammonium is dependent on the protein content of the feed, temperature and salinity. The main criterium for these calculations is to dimension the biofilter such that TAN will come below 1.5 mg/l in the fish tank. Water flow and the time of retention in the fish tank are also important factors in such a calculation. CO2 is removed by a traditional ripple filter. Bio-blok is a good medium, suitable for this purpose and it is important with good access to air for an efficient CO2 extraction. In order to calculate the correct dimensions for the aeration system, it will be necessary, as with the biofilter, to take into account the biomass present in the fish tank, amount of feed, O2 consumption and water flow. The system should be dimensioned in such a way that the maximum value in the fish tank is below 15 mg/l. The necessary amount of water to keep this limit, or measured as retention time in the tank, will be 37 minutes when the system is performing at maximum capacity. Fact box: Dimensioning of water treatment Biofilter Choose one common system for both units, MBBRTM: K3 chip, 355m3. Reactor volume: 710 m3 divided into two chambers. Area: about 175 m2 CO2: Bio-Blok80, 4 layers – Area: about 78m2. 36/37.5 min retention time in the tank, Maximum amount of water: 7125m3/h Oxygenisation: Oxygensupplier per tank

Economy Construction of an onshore post smolt system will obviously involve bigger investments than a corresponding system in an open cage. As an example of the costs involved in a land based recirculation system for salmon, AquaOptima has designed and delivered systems for food fish production of Atlantic salmon with a capacity of 1000 tonnes/year to China. The total cost of investment was about 7500 kr pr m3 farming volume. Converted to Norwegian conditions, this will correspond to about 10000 kr pr m3. An important fact to take into account is that an onshore system like this can have fish densities 3 times as high as those used in open cage systems and thus the cost of investment can be shared by a higher biomass produced.

The pumping costs and oxygen consumption will increase the production costs in such a system compared to cage systems. The energy cost for the pumping and heating of water and oxygen production make up about 10% of the production costs of such a system. However, it is expected that reduced losses, increased fish health, simplified use of localities/operations and better MTB exploitation will lead to positive numbers at the bottom line for such a production strategy.