Fatty acid funding secured

A project that aims to develop the use of microorganisms to ferment methane into long chain omega 3 fatty acids has been launched by the University of Nottingham’s Synthetic Biology Research Centre, alongside the biotechnology company CHAIN Biotech and industry partner Calysta, Inc.

The pioneering project is called PUFA (polyunsaturated fatty acids), will run for a year and is being funded by industrial biotechnology catalyst grants from InnovateUK and the BBSRC, with potential further significant scaling up investment from Calysta - which is already committed to providing the aquafeed industry with microbial protein.

Leading the research at Nottingham’s Synthetic Biology Research Centre, Professor Nigel Minton said: “We specialise in the use of fermentation of certain gases to produce sustainable industrial chemicals and biofuels and now, through this project, to produce vital feedstock ingredients like Omega 3 fatty acids. We will be engineering the Methanococcus microbe to produce polyunsaturated fatty acids from a cheap and replenishable feedstock – methane gas.

“There are huge potential benefits in terms of reducing dependency on fishing and also creating a new use for a plentiful gas that has a harmful effect on the environment if unharnessed. Methane is a low cost and sustainable feedstock that can be produced from a variety of renewable sources, including anaerobic digestion which is now prevalent in the UK and EU.”

Dr Basil Omar, Chief Commercial Officer at CHAIN Biotech, said: “This is a great example of how publicly funded early stage research is being leveraged and commercially exploited with an industry partner to scale up successful discoveries made in the lab. This highly innovative project will draw upon CHAIN’s world leading expertise in Synthetic Biology to improve production characteristics by targeting both cell growth and product yield simultaneously with a focus on Omega 3 fatty acids. We hope it will offer a cheaper route to a high demand product with positive environmental and social knock on effects.”

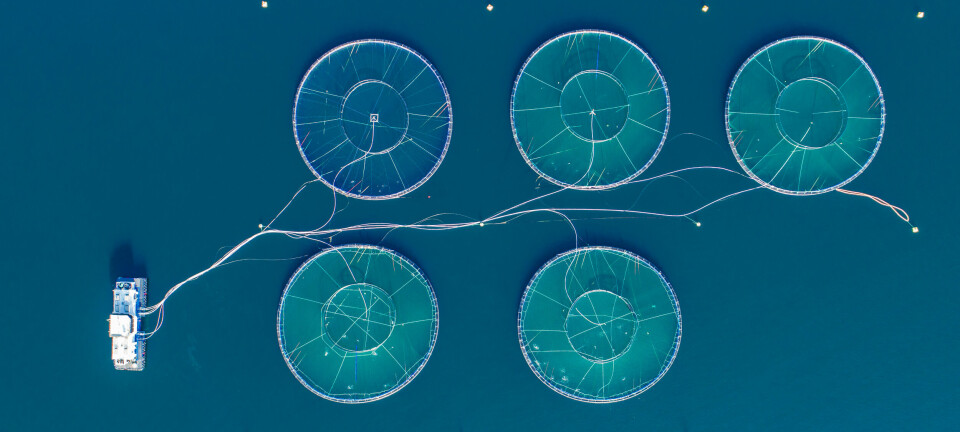

Calysta, the project’s commercial partner, specialise in the production of microbial proteins for the commercial fish feed and livestock markets. Microbial proteins are already used to make foods like the popular savoury spreads made from yeast extract. Fish farming is growing in response to increased global demand for seafood and Calysta has developed and is commercialising a new patented product called FeedKind protein to provide a sustainable fish food ingredient for the fish farming industry. The company will offer a fast track to scaling up of the PUFA manufacturing process. Calysta is based in California and will open a market introduction facility for FeedKind in Teesside, England, later this year. A commercial-scale plant in the US is expected to come online in 2018.

Dr Alan Shaw, Calysta President and Chief Executive Officer, said: ”Partnering the University of Nottingham and CHAIN Biotech in this project means we can develop the next generation of FeedKind protein.

“FeedKind protein is a natural, safe, high-quality, non-GMO protein source produced by a single cell organism, using a natural, proprietary fermentation process. By replacing fishmeal, fish oil and soy protein concentrate with a nutritious naturally occurring protein, the aquaculture industry can reduce its impact on the environment and on wild fisheries while continuing to grow to feed the world’s population.

“Successful completion of this research will result in a step-change in sustainable human nutrition and will be welcomed by the food industry, retailers and consumers globally.”