Pioneering closed containment system stocked

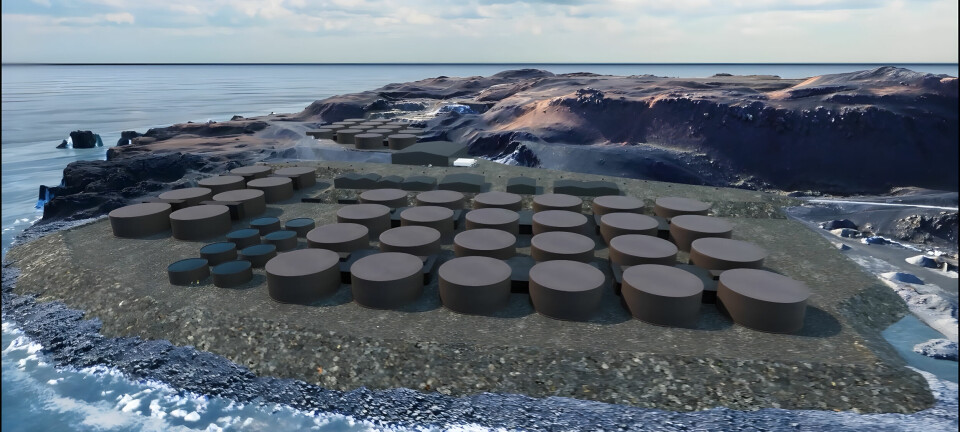

Marine Harvest has finally stocked its first smolts in its pioneering Neptune 3 closed containment unit in Skånevik.

“The transfer has gone smoothly, and so far it looks very good,” Operations Manager, Jan Erik Jensen told kyst.no.

The company originally planned to stock its first smolts in May 2016 but this was later postponed to November this year, after Marine Harvest and Aqua Farm Equipment decided to conduct more tests before stocking the unit. Operation Engineer Jan Erik Jensen told kyst.no that they put out 169,000 smolts in the cage last weekend. The plan is to grow the smolt to about one kilogram before moving them into open cages. The first batch were supplied by Vågafossen Settefisk.

The Haugesund-based company AquaFarm Equipment AS has designed and created the concept, which has been tested at MH’s R&D site in Molnes.

“We need more research, development and knowledge of salmon production in enclosed structures. Molnes will give us valuable experience in this area. We have tested earlier versions of this cage in Molnes, learning valuable lessons,” says Ragnar Joensen, MH’s technical manager.

Atle Presthaug from Aqua Farm Equipment says they are confident the technology used in Neptune. “We look forward to gaining more experience from this stocking of salmon on Molnes and will follow the production closely in collaboration with Marine Harvest,” he adds.

Details

The Neptun 3 is made of fibreglass and has a 40m diameter on the inside, and a circumference of 126m. It is 22m deep and has a 21,000m3 capacity.