Krill harvester pledges net zero emissions by 2050

Fish feed ingredient supplier Aker BioMarine has announced plans to halve carbon dioxide per tonne of krill produced by 2030 and reach net-zero emissions by 2050.

The plans include using “green ammonia” to fuel the company’s vessels which harvest krill in the Antarctic. Krill and krill oil have been shown to have beneficial effects when added to salmon feed.

At the end of February, Aker BioMarine and a sister company, Aker Clean Hydrogen, signed an agreement and are teaming up with other key players to industrialise the production of green ammonia, in an industry first move.

Carbon-free ships

Aker Clean Hydrogen was launched last month to develop, build, own, and operate clean hydrogen production at scale, leveraging domain expertise across parent company Aker group.

This will support Aker BioMarine’s mission to make its vessels completely carbon-free. Its newest support vessel, Antarctic Provider, is equipped with the most energy efficient engine in the world, a hybrid engine that is convertible for greener fuels of the future.

Sustainable fuel

“Green ammonia is the most promising sustainable fuel for the shipping industry. It is essential that the industry tests and develops solutions for ammonia on a large scale,” said Christina Ianssen, sustainability manager at Aker BioMarine.

Aker BioMarine plans to have vessels that are using ammonia as fuel towards 2030, when the infrastructure for production and distribution of green ammonia is in place.

The company also plans to reduce the amount of fuel used to locate krill through use of ocean drones and flying drones. These devices minimise the time harvesting vessels need to spend searching for krill.

Aker BioMarine has already deployed its first ocean data drone with the aim of significantly reducing financial and environmental costs and collecting scientific information. All the drones collecting data operate with zero emissions.

50% reduction by 2030

In the last ten years Aker BioMarine has cut its CO₂ emissions per tonne of krill produced by approximately 50% and plans to do the same again in the next ten years.

It said it had already implemented several sustainability initiatives towards its goal, such as implementation of analytical tools to reduce consumption of consumables and energy at its manufacturing plant in Houston, Texas, reuse of energy and efficiency projects on the vessels. These initiatives have put the company on course to reach its 2030 targets.

Aker BioMarine has signed off on eight sustainability commitments to be achieved by 2030. These include ensuring full circularity on all of its principal waste streams and helping to decarbonise aqua and animal feed by delivering low-carbon marine ingredients.

“These sustainability goals support our overall purpose – to improve human and planetary health – and make this purpose even more tangible,” said Ianssen.

“Every single person working in Aker BioMarine is involved in achieving these goals, and we will work across the company’s entire value chain to make sure we lead the way to a net zero end.”

What is green ammonia?

Green ammonia production makes use of renewable energy sources such as hydro-electric, solar power or wind turbines.

Unlike “brown” ammonia, which is made using fossil fuels (typically natural gas) as the feedstock, the raw materials for green ammonia are hydrogen obtained through the electrolysis of water, a process powered by renewable energy sources, and nitrogen obtained from the air using an air separation unit. Green ammonia can then be synthesised from nitrogen and hydrogen via various methods, with the Haber-Bosch process currently the only method used on a commercial scale, says Norwegian fertiliser company Yara.

Similarl to fossil fuels, ammonia is both a chemical energy carrier and a potential fuel, where energy is released by the breaking of chemical bonds. Crucially, ammonia has the advantage of not releasing any carbon emissions if used as a fuel, and its green credentials can be enhanced even further if sustainable energy is used to power the production of ammonia.

A European first

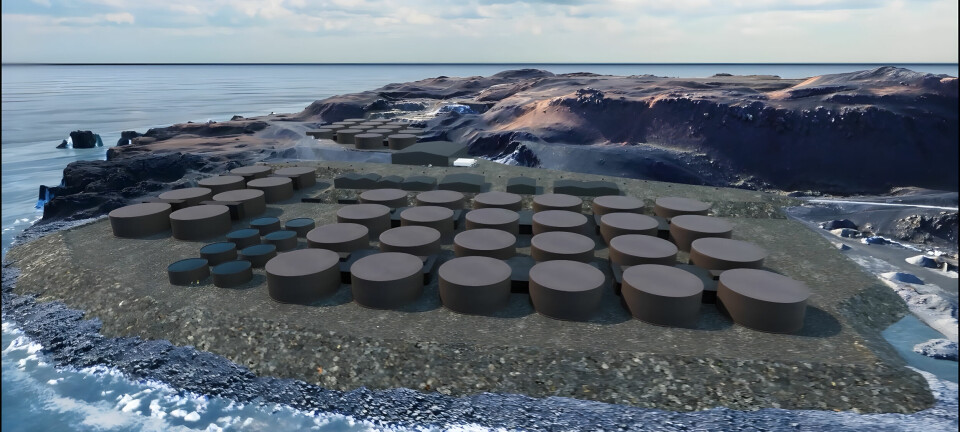

Yara, renewable energy supplier Statkraft and Aker group’s green sector subsidiary Aker Horizons – which owns Aker Clean Hydrogen - aim to establish Europe’s first large-scale green ammonia project in Norway. The partners will target green hydrogen and green ammonia opportunities within shipping, agriculture and industrial applications, by electrifying Yara’s existing ammonia facility in Porsgrunn, south of Oslo.

The project has potential to remove about 800,000 tonnes of annual greenhouse gas (GHG) emissions – the equivalent of 300,000 cars – representing what could be the largest climate initiative in Norwegian industrial history.

Aker Clean Hydrogen has a portfolio of nine clean hydrogen projects and prospects with a total net capacity of 1.3 GW under development, and additional pipeline and opportunities of 4.7 GW. The company aims to reach a net installed capacity of 5.0 GW by 2030.

Projects include partnering with Mainstream Renewable Power to unlock the green hydrogen and ammonia economy in Chile.