Closed-cage maker chooses ‘ideal’ aluminium for collar

The makers of an in-sea closed salmon cage have switched from steel to aluminium for the cage’s floating collar to take advantage of the metal’s lighter weight and the fact that it doesn’t rust.

Norwegian manufacturer Ecomerden made its first cage with a steel collar for salmon farmer Sulefisk but has an order from another fish farmer for four more cages, which it will produce with aluminium collars after teaming up with aluminium producer Hydro.

Jan-Erik Kyrkjebø, general manager of Ecomerden, said: “Working with Hydro on developing this concept, we both had the same goal – to improve productivity and welfare standards in offshore fish farms, while controlling costs.

“It turns out aluminium is the ideal material to meet our needs, as a high-performing and cost-effective option, creating new opportunities for growth.”

Heavy-duty flexible wall

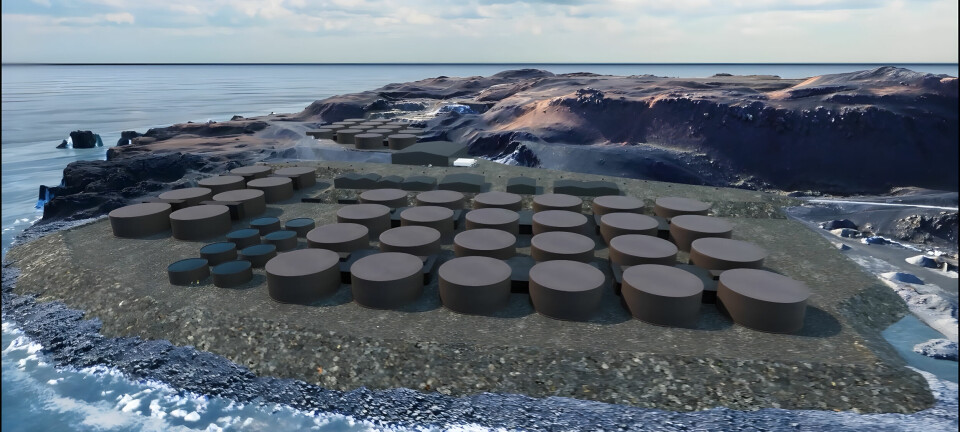

The cage, also called Ecomerden, is a self-contained closed cage construction where the floating collar is a rigid metal frame designed to withstand tough conditions. All necessary equipment is built into and protected by the floating collar.

A heavy-duty flexible wall keeps out sea lice, and water is drawn in from a depth below the layer of water in which the lice live.

The material for the wall is specially designed and constructed by French manufacturing group Serge Ferrari, a leader in flexible composite materials. There is also a net inside the Ferrari wall.

800 grams

Sulefisk has used its Ecomerden to grow smolts from 130 grams to 800 grams before setting them out in open cages.

Kyrkjebø said that removing the necessity to treat fish for lice until they were moved to open cages had led to stronger, healthier fish.

Pancreas disease (PD) and amoebic gill disease (AGD) were detected at the Sulefisk site, but the fish from the Ecomerden continued to grow with high survival dramatically greater than the fish that had been set out in open cages from 130g.

Kyrkjebø said the four cages Ecomerden is making will be used in conjunction with open cages. Smolts will be grown to a large size in an Ecomerden and will then be distributed among seven open cages. Some fish may also be left to grow out in the Ecomerden.

No maintenance

Marijn Rietveld, Hydro’s market director of marine and offshore, said: “Aluminium is well suited for application in the offshore industry. It does not rust, requires little maintenance and weighs only a third of steel. As the offshore farming industry is growing, we believe more and more will discover the advantages of exploring what aluminium can offer.”

Hydro said making rings in aluminium eliminates the need for maintenance and saves the significant cost of surface treatment maintenance.

The ring will be supplied by Hydro’s plant in Finspång, Sweden.