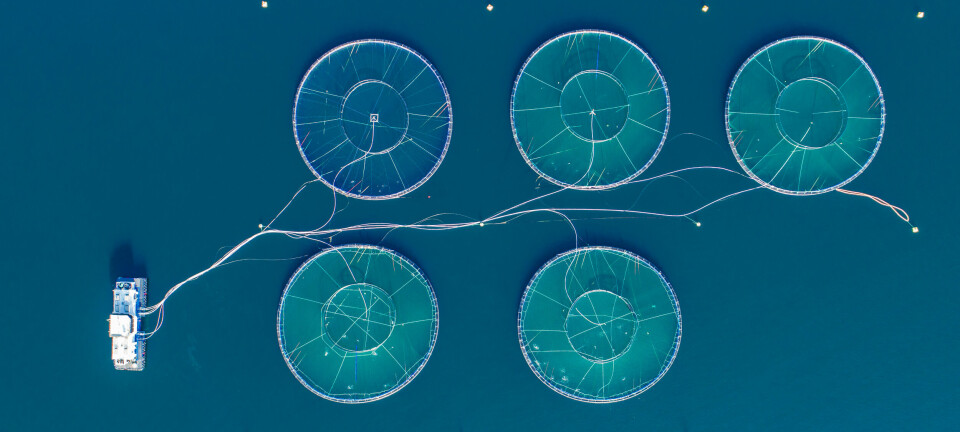

The new face of offshore salmon production

Nordlaks wants to invest billions in offshore vessels that can act as salmon farms without the risk of escapes and sea lice.

“We can create a new era in Norwegian aquaculture,” Nordlaks’ Inge Berg told Blv.no.

Inge Berg and Nordlaks, together with other Norwegian partners, have been working quietly on a long term project to develop new technology for closed containment production of salmon on ships and have now applied to the Norwegian Ministry of Fisheries for four development licences.

Each ship will be 430 metres long by 54 metres wide, and will be anchored to the sea bed using technology from the offshore industry. They will have the capacity to produce 10,000 tonnes of salmon per cycle.

The constructions are designed to withstand wave heights of 10m and can be raised to four meters in storms. The seafarm will be 10m deep act like a steel frame for six 50 x 50m cages that are equipped with 60 metre deep nets. Each facility will cost between NOK 600-700 million (£46-54 million).

“The design protects against external influences such as escapes and we expect to keep the lice away,” says Berg.

The seafarm will have a permanent crew of five to six men who will have a separate living unit on board. They will be anchored using suction anchors, which are sourced from the offshore industry, and the vessels will be located in the open sea, at least ten kilometres from other installations.

“We will use known technology from the aquaculture industry, shipping and offshore. We can undertake this project. We have skilled and committed professionals with us, and Norway has the best knowledge in all these areas,” Berg said to the online newspaper Vesterålen.