Shetland

Shetland is one of Scotland’s aquacultural powerhouses – producing around one third of the country’s salmon as well as 90% of its mussels. Its fisheries and aquaculture industries combined produce £300 million a year – making them more important to the islands’ economy than even oil & gas.

According to David Sandison, head of the Scottish Salmon Producers’ Organisation (SSPO) in Shetland, the islands are forecast to harvest around 40,000 tonnes of salmon this year, up from around 37,500 in 2014. In 2014 the salmon industry provided 448 direct full time jobs, with the total of ancillary (including part-time jobs) bringing the figure to over 1000.

According to the SSPO’s latest Industry Economic Report, in 2014 Shetland’s aquaculture industry attracted £17.8 million in capital investment; paid out £12.9 million in salaries and inspired a local industry spend (on all services required to support production) of roughly £30 million.

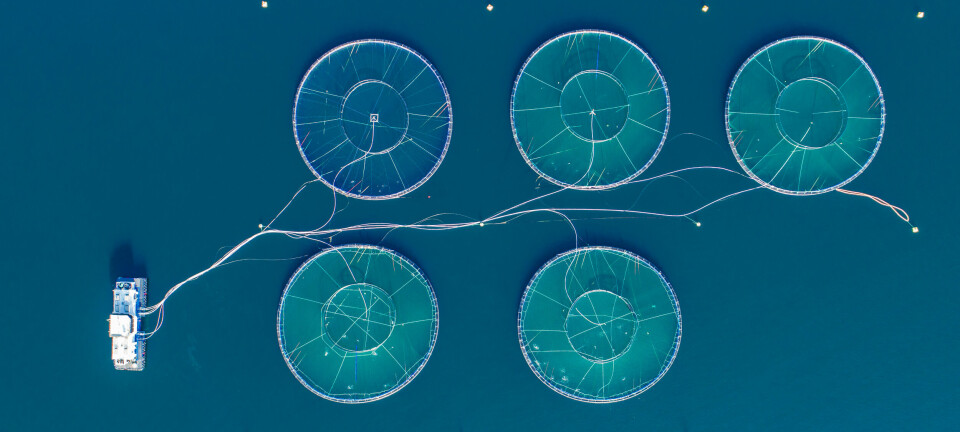

The main salmon producers on the islands are Scottish Sea Farms, Cooke Aquaculture and Grieg Seafood Shetland and there are still two independents, Thompson Brothers and Balta Island Seafare, with a total of up to 75 sites active at any one time.

The industry has greatly consolidated in the last decade, David explains, “10 companies were operating in the Scalloway area, for example in 2007, and there are only two companies operating there now. “The essence of it all is that we now have a well-developed, well-invested, well-run salmon sector in Shetland and there is a great deal of pride in that.”

Cooke

Aquaculture

Cooke took over Meridian’s former sites from Marine Harvest in 2014

Cooke Aquaculture bought the sites previously run by Meridian from Marine Harvest in 2014, bringing a welcome dose of stability to its employees, who were waiting to find out their fate for over a year, while the Competition Commission decided whether Marine Harvest was allowed to retain the sites after its purchase of Morpol.

The move by Cooke – a family-run Canadian company headed by Glen Cooke – marked their first involvement in the Scottish Aquaculture industry. Cooke’s Shetland Regional Manager, David Brown, says: “The takeover has been very good for everybody and now that the uncertainty is over we can concentrate on farming fish”. David reflects that the company is looking to slowly ramp up its production levels in Shetland from about 11,000 tonnes a year. This includes the stocking of a site at Aith that has lain fallow since 2009, while the recent purchase of Thompson Bros Salmon at the end of July will add two sites and about 2,000 tonnes a year to their production total.

New equipment is already beginning to arrive, most recently in the shape of a new 14-metre catamaran, Sapphire, which will act as the support vessel for all its 20 sites in Shetland, which arrived when Fish Farming Expert were visiting the islands at the end of June. David said he was “delighted” by the new 65 tonne delivery and impressed by its capacity to offer more power at a time when the company is busy beefing up its sites.

Sapphire: the first in a two vessel contract between KJ Hydraulics and Cooke Aquaculture

The workboat was developed following a meeting at Aquaculture UK in Aviemore last year and was designed and built by KJ Hydraulic – with the steel and aluminium work taking place in Riga, while the design and fitting was done in the company’s home port of Fuglafjordur, in a process that took 5-6 months.

Excitingly for Cooke, a sister vessel is currently under construction and is due to be delivered to serve their Orkney sites this September and KJ’s CEO, Olavur Olsen, who personally delivered Sapphire to Unst, told Fish Farming Expert: “We have been looking forward to this opportunity and hope it will be a very good tool for them. We’re aiming to produce more vessels for the Scottish market.”

Some of Cooke’s smolts on Shetland come from its hatchery on Unst, which employs 9 people and currently produces 70-80g S1s and S0s each year, in a flow-through system that takes its water from the Loch of Cliff – the largest body of freshwater on the islands.

While, as hatchery supervisor John McCulloch admits, “the setup might be a little outdated compared to the new generation of RAS systems, it’s a good site and benefits from being able to move the fry into the loch at 2-3 grams, where they have extremely low stocking densities.” The company also has hatcheries on Mainland Scotland and in Cumbria producing a total of 7-8 million smolts per year. In terms of seawater production it has 5-6 sites in Yell, 3-4 around mainland Shetland and 8-9 in Unst. It also farms an additional 6-7,000 tonnes in Orkney.

Health issues

The company benefits from the tidal nature of a number of their sites, although they have seen some AGD in the last few years. “It’s very tidal up here,” David explains, “historically we have very few problems with lice and there has – thankfully – been not too much AGD about this year and we’ve learned a lot from the AGD outbreaks last summer. “We found that tarpaulin treatments have been the most effective and we’re ready for it should it reappear. We could treat any site tomorrow if we needed to.”

Further investments

“A new multi-million pound project is going to convert an old crab factory in our new processing facility, we’re also due to receive 14 new 100m Fusion cages soon and new mooring grids are going to be installed by Inverlussa Marine.

“Everyone is very happy to see the level of investment Cooke are putting into the operations in Shetland,” David observes. Another new project will involve stocking lumpfish into several of the company’s sites, in a project that is being undertaken in conjunction with Grieg Seafood Shetland and Scottish Sea Farms, who will be conducting similar trials in the same area.

David explains: “The Shetland industry is working together to help eradicate lice. We’re looking at stocking about 70,000 lumpfish this year, at a ratio of about one for every ten salmon per cage. “All in all we are very positive about the future of the aquaculture industry in Shetland".

Scottish Sea

Farms

Scottish Sea Farms (SSF) currently has 10 active sites in Shetland, which produce 9-10,000 tonnes of the company’s overall harvest of around 31,000 tonnes a year and has plans to continue to grow its capacity in both Shetland and Orkney. They have progressively reopened sites in Scalloway over the last two generations as the new regulations and coordination between farmers brings more confidence in sustainable production.

A map showing the location of SSF’s sites in Shetland

SSF is currently in the midst of a recruitment drive aimed at school leavers, emphasising the impressive technology at the disposal of contemporary salmon farmers and the huge range of jobs – from microbiology to engineering appointments – that are available within the company. The company has recently been awarded two Investors in People awards, one for Investors in Young People, as well as Best Aquaculture Company at June’s Crown Estate Marine Aquaculture Awards.

Processing

Its main processing hub is located in Scalloway, where it guts all the company’s fish from Shetland, Orkney and Loch Eriboll on the north coast of mainland Scotland. Run by David Laverty and manned by 70 full time staff, with 35-40 on site at any one time it can process 20,000 fish (roughly 100 tonnes) per day through three Baader 142s.

SSF is the exclusive producer of Marks & Spencer Lochmuir salmon, which accounts for 30-40% of its total production volume. SSF also sell to a number of UK retailers, including Tesco and Waitrose, and produce Label Rouge salmon sold into France and other export markets. So far this year, the fish have averaged a very respectable 5.4 kg apiece after only 14-15 months at sea – an excellent growth rate.

Cleaner fish

Although it has been heavily involved with the Machrihanish wrasse project – which earned it the Crown Estate’s Stewardship Award in June – SSF has decided to use lumpfish as an alternative means of lice control in its Shetland sites. “We originally planned to use wrasse as cleaner fish here too,” explains Noelia Rodriguez, SSF’s Fish Health Production Biologist in Shetland, “as our wrasse trials, which have taken place at all our mainland sites – have allowed us to reduce lice treatments by at least 80%, with some sites stocked with the cleaner fish requiring no treatments at all. “However, our last experience of wrasse in Shetland – in which the wrasse in three of our salmon sites were found to be infected with VHS – made us reconsider our options.”

“We also felt that lumpfish, which can eat lice when the water temperature falls as low as 2-3°C, would be a better fit for our Shetland sites, as the water temperature is generally lower, while wrasse stop feeding below 7-8°C.” “The first batch of lumpsuckers will be provided by Ardtoe in mid September,” Noelia explains, “and will be stocked at between 10 and 15% [of the salmon number per cage] and will be monitored and looked after by a dedicated lumpsucker specialist on site.”

Predator problems

Another advantage of SSF’s move into lumpfish is that they fit in well with the company’s new anti-seal netting – with a double net system combining W&J Knox’s soft, 18mm ‘Star net’ – which is small enough to contain lumpsuckers – on the inside, with the tougher ‘Sapphire Ultra-Core’ on the outside. The net was made to a Knox design, but the netting was developed and produced by Knox's Indian partners, Garware Wall Ropes. Both are plastic, so need no anti-fouling, which is a further advantage.

First trialled by the company at one cage at its Loura Voe site, which has been plagued by seals over the years, since January the producer has been so impressed that it has already decided to replace the nets in all 10 of its 80-metre pens at both Loura Voe and nearby Grunna Voe with the new arrangement.

Kimberley Izdebski, site manager at Loura Voe – and the first ever female site manager in Shetland – has been supervising the net changes and reflects: “We’ve been using 20 Mohn Aqua projectors to try to keep the seals out, but while these certainly make a difference, it seems the seals return when their hearing comes back to normal.

“The stress from the seal attacks has meant that there have been a number of lean fish this generation but within a month of installing the new nets the fish put back on their condition and there have been virtually no morts.”

Meanwhile, down in Orkney, where some sites have restrictions on the use of ADD’s, SSF are trialling a combination of novel ADD (under trial licences) and predator resistant netting.

Self-sufficiency

The company tries to be largely selfsufficient in its Shetland sites. “Although we do hire divers,” Noelia explains, “since April 2013 we’ve stopped using wellboats for lice and AGD treatments, preferring tarp treatments, which we can do ourselves, instead.” Their engineering department in Scalloway has also come up with a couple of ingenious inventions of late, including a special net-changing roller on the back of one of the their workboats which allows them to change nets without trapping the fish in the pens against the back of the boat.

Grieg Seafood

Shetland

In 2014 the company produced around 19,500 tonnes from it Scottish sites – most of which are located in Shetland, as well as four on Skye – and is projected to harvest 17,000 tonnes in 2015, a decrease largely attributed to problems with AGD and PGD suffered by the company’s 2013 generation.

Under the guidance of Sigurd Pettersen, who replaced Michael Stark as MD two years ago, the company is going through a transitional period, with some exciting projects coming onstream, while others are being closed down. Having performed similar tasks at Golden Sea Produce – after the ISA crisis in 1998 – as well as at Lerøy Aurora, he is able to draw on considerable experience as he seeks to turn the company’s fortunes around – a process he says that “takes at least two years” and he has recently agreed to an 18 month extension to his contract, in order to finish the job.

“This is the third time I’ve done it and it’s simply a question of common sense,” Sigurd reflects, “simplifying and focusing on the basics.”

One recent change inspired by the Norwegian’s arrival is its name, which became Grieg Seafood Shetland (GSS) in July, following an amalgamation of Lerwick Fish Traders, Hjaltland Seafarms, Hjaltland Hatcheries and Shetland Products.

While the change is largely cosmetic, it will make life, accounting and all manner of paperwork considerably more convenient for the firm. As Sigurd reiterates: “What we do now reflects the strategy chosen over the last two years to improve the company’s operation: simplify and focus.”

Girlsta hatchery

A project that is likely to form the bedrock of GSS’s rebuilding programme is the recently completed RAS smolt unit at Girlsta. The impressive £15.8 million facility hatched its first eggs in July last year, but only had its official opening this June having been under construction for over two years. It will be able to produce 5 million 200g smolts each year when fully operational.

“The shift towards larger smolts means the fish should only need about 18 months at sea, as opposed to the current 24-month cycle, so mortality rates should be considerably lower,” says Sigurd, who has high hopes for the facility.

“It’s a first for Shetland and a first for Grieg and it’s a necessary step for the company. It’s is similar to the company’s RAS hatcheries in Norway and Canada and has been installed by some of the same companies, but is the first of the Grieg Seafood group’s RAS hatcheries that has been built from scratch. All the others – at Finnmark and Trostovaag in Norway, and in BC – were flow-through facilities that have since been adapted,” he explains, “and we will be the most efficient hatchery within the group.”

The new hatchery employs 16 people, many of whom are new to salmon farming, so the company is working on its protocol – no easy task given that fish are constantly being moved around between the facility’s egg, fry, parr and smolt units. Indeed, as Jon Walden, who has been working on the site since 2012 and took over from John McEvoy as manager in 2014 reflects: “The conveyor belt is now rolling and we’re flat out producing fish.

We had 1.2 million in and 1m out in the same week recently – it’s relentless”. “One of the main challenges is getting eggs from our suppliers [Stofnfiskur, SalmoBreed and AquaGen] when we want them, not when it suits the suppliers, and there’s a bewildering complexity to the whole set up. It’s been an intensive learning process, but it’s easy to forget how far we’ve come in the last six months.”

Progress is indeed being made and the first batch of 358,000 smolts, which averaged over 150g, were transferred to one of the company’s sites at Setterness at the beginning of May and have experienced very few mortalities. Jon reflects: “We had very positive feedback from the wellboat, from divers and from the guys on site – it’s been the lowest level of mortalities we’ve ever recorded in Shetland – only 16 smolts were found to be dead in the cages during the first 24 hours and only two died in the wellboat, which is pretty remarkable”.

The success is all the more so because this batch were transferred using a previously untried method. “We can’t transfer the fish directly onto the wellboat – because it’s a recirc system we can’t afford to pump out all the water: not only would it have a serious impact on the biofilter, but we’ve also been looking after the water – ensuring it’s the right temperature and pH – so the last thing we want is to pump it all into the sea.

“As a result we had to come up with a way to de-water the fish, so the vast majority of it stays in the system. The only way to test the system was to use it to transfer fish, but thankfully it seems to be working well,” Jon continues.

A second batch of smolts was transferred to other sites in Setterness in July and these are also reported to be thriving – marking a very promising start to facility. “Every production run gets closer to the standard we want,” John explains, “but the system throws up so many surprises that it will probably take a couple of years to master the process”.

“We will have spare capacity, but are keeping our external contracts just in case. In time we might have potential for external sales, but it’s neither a priority nor in our business plan – we need to get our own house in order first,” Jon observes.

GSS and SSPO

Another interesting development that could arise from the company finally being self-sufficient in smolts for the first time is that it will, in time, open the door for GSS to be reinstated into the SSPO. The company was expelled from the organisation in 2013 for importing smolts from Norway – a move that, while legal, was in breach of the SSPO’s Code of Good Practice (CoGP).

However, Sigurd says that a return to the PO is “not a priority”. “It is improbable that we will be allowed back in until after I have left, so it’s not a priority for me. It will be their call and their decision,” he explains.

Changes at sea

GSS’ sea sites have also seen a number of changes under Sigurd, including their involvement with Cooke and Scottish Sea Farms in a lumpsucker project. However they are in fact ahead of the other companies, as they have had lumpsuckers deployed in a number of cages since the end of last year.

“We’ve learned a lot from the first batch,” Sigurd explains, “and they’ve been growing well in the salmon cages but if the lumpsucker trials take off there will be a need to develop a feed for the lumpsuckers and specific lumpsucker vaccines. We’re currently using old cod vaccines, but there’s at least one company currently working on specific ones for cleaner fish.”

In the long term, says Sigurd, Shetland’s salmon farmers will need almost 1.5 million lumpfish to cover all the islands’ salmon sites where treatments are currently needed, in which case a dedicated local lumpsucker facility would be required – a project which is currently being considered by Norwegian company Ryfylke Rensefisk. GSS is also keen to try the new SkaMic “fish wash” system – for more details see page 26 – to help bolster their chances in the battle against lice.

As well as lice, GSS is also trying to tackle the seal problem by installing a number of new predator nets, including the EcoNet, the Badinotti HDPE and Hvalpsund nylon super mono in 25mm2 at a number of key sites. Meanwhile they are also set to benefit from having a reliable source of smolts from Girlsta, meaning that one net size should suffice and the 80mm nets are, according to Sigurd, easier to keep tensioned, acting as a further obstacle to predators.

Processing changes

While the new hatchery is going to provide the bedrock of GSS’s production, their processing operations have also been going through a substantial change and Sigurd felt compelled to close down their value-added lines – which had been producing the Wildwaters range of smoked salmon products for a number of years – in March.

“We had several listeria outbreaks in the last few years which tarnished our reputation in the market, so we decided to mothball our VAP production,” Sigurd reflects. “We now only sell HOG fish through Ocean Quality, a company we jointly own with Bremnes Seashore, and will no longer produce smoked salmon.

“The sector is very, very competitive and we’re too big to fulfil niche production but too small to compete in the bulk market with companies such as Morpol, which produces some 70,000 tonnes of smoked salmon a year, Marine Harvest’s new site in Rosyth, and companies such as Laberie and Delperot in France. We may sell some fillets in the future though.”

The move led to GSS laying off half of its factory workforce, but on the plus side there have been “close to zero listeria readings” since, according to Sigurd.

Service

companies

Johnson Marine

Former salmon farmers Ivor and Angus Johnson sold up their farm sites – which produced up to 11,000 tonnes per year – in 2009 (at which time they were the biggest producers in Shetland) and have since amassed a fleet of 5 wellboats, 4 netwashers and 2 workboats.

During 2015 these will harvest almost 50,000 tonnes of salmon – almost a third of Scotland’s total production and a considerable increase on last year’s total of 35,624 tonnes. The producers who currently use Johnson are Cooke Aquaculture, Scottish Sea Farms, The Scottish Salmon Company, Thompson Brothers and Balta Island Seafare. Johnson Marine also aims to wash over 5,000 nets – mostly in Shetland, Orkney and the West Coast of mainland Scotland – this year, up from 2,802 in 2014.

The brothers have also invested in, and even invented, new technology and their latest technological addition – a remarkable and innovative piece of licecleaning kit – arrived in Shetland aboard the newly acquired Rune Viking in July. Made by SkaMic, the “fish wash”, as it has been dubbed by the Johnsons, is a treatment-free means of removing lice from salmon. Although the system is still relatively new to the market, the brothers have been so impressed with what they’ve seen that they’ve already ordered two more to fit on a pair of their existing vessels – a serious vote of confidence given that each system is worth a cool £750k.

Fish are pumped through the system in less than a minute and the SkaMik removes lice through a combination of soft brushes and jets of water. Those lice which are knocked off are then collected and captured in a drum filter, allowing them to be disposed of in a biosecure manner.

As Ivor explains: “The system has only been installed on the Rune Viking for about six months, but it has already been capable of removing lice from 70-80,000 tonnes of salmon. In the right conditions it can process up to 100 tonnes of fish in an hour.

“Although we’ve not signed any contracts yet, we’re hopefully going to do some work for all the salmon producers in Shetland, and perhaps further afield.” And given the successful implementation of a trial with GSS in July – in which “80- 90% of the lice were removed” – it seems to offer a good alternative to chemical treatments.

The company’s next SkaMic system is due to arrive in September and, by the time the third arrives, the Johnsons’ workforce will have risen by 16 people – no mean feat given their isolated location and a real boost for Shetland’s job seekers.

The North Atlantic Fisheries College

The North Atlantic Fisheries College (NAFC) has had a key role in underpinning and strengthening the islands’ aquaculture industry, not only by giving school leavers their first insights in the business, but also – in increasing numbers – by offering short training courses to farm workers who are seeking to gain Modern Apprenticeships.

Operated and instigated by Kenny Gifford, who has run the programme for a number of years, he is about to retire and will be replaced by Stuart Fitzsimmons. The two of them have not only already helped to guide over 100 farmers through their level 2 and level 3 apprenticeships, but also devised the content of each module, after consultation with the local salmon farming companies. “Funded by SDS, some of the salmon companies are also offering employees financial incentives to progress to Level 3,” says Kenny, “and anyone with at least six months’ experience on a farm can enrol for the course. It’s not set in stone, but we find that this helps us avoid people dropping out due to inexperience.”

“There are currently 31 farmers under assessment and potentially another 6 signing up before the end of the year and there will probably be 26 placements made available next year,” Stuart explains. “The system has proved very popular with both farm workers and the companies themselves, giving the workers more confidence and often very transferable skills,” adds Kenny.

Each qualification has been devised after consulting the industry about what topics it would like to see covered and where it sees there being the greatest need for training. This has resulted in the development of a huge range of modules, covering subjects such as fish health and welfare, feeding control, AGD and lice.

Due to recent developments in the industry level 2 now includes a biological control module, which focuses on wrasse and lumpsucker husbandry – proof of how the qualifications are evolving parallel to industry developments.

With training and examination taking place both onsite and in-house, Kenny and Stuart are now well known to farmers throughout Shetland and the Orkney Isles – being regular visitors to numerous sites – and they have just recruited Laurence Pearson, who has extensive experience in the islands’ fish farming industry, as a new trainer and assessor.

“Training is a compulsory part of the latest version of the SSPO’s latest Code of Good Practice (CoGP),” reflects Kenny, “and the introduction of the Scottish Technical Standard, in June, will also act as an added incentive for companies to improve their training regimes”.

The college has also devised a National Progression Award in aquaculture, for school children, which is gaining in popularity.

Aurora Marine

One of the newest aquaculture ventures in the Shetland Isles, the specialist net cleaning company Aurora Marine was set up by Colin Leask in 2012, on the back of his experience as both a salmon farmer and pelagic fisherman. “While I was away at the fishing,” Colin explains, “we often landed our catch in Norway and I became aware of the remotely operated net cleaning systems that they used on farms over there.”

“Having worked on salmon farms for many years, I knew how difficult and time consuming it was to clean nets manually, and thought this new ROV system, made by MPI, was a great idea. It has up to nine cleaning heads, is steered with 8 thrusters and includes a 360° camera, meaning that it can inspect the nets and also record the footage. It can also clean the bottom of the nets which was previously not possible.

“At that time it has never been used in Scotland but I knew it was going to be big and so I had a vessel specially made for the purpose.”

Plans for the company’s first custom-built vessel – called Aurora – were drawn up by Marin Design and the boat was built at the Viknaslipen shipyard. The 13.8m vessel has since been contracted to Meridian (which has since been bought by Cooke Aquaculture), cleaning the company’s nets every two weeks in summer and every three weeks in winter.

“It came at a time when they were stopping using anti-fouling nets,” explains Colin, “and we’d agreed on a deal before the vessel was built.” Colin now employs four full time workers and the vessel itself is operated by a twoman crew, who work on a one week on/ one week off basis.

Excitingly, he has also just completed a deal for a second vessel, which is going to be designed and built by the same team and is scheduled to be delivered to Shetland in April 2016.

Colin looks to expand the company in line with the expansion of Cooke Aquaculture, to be in a position to fulfil their growing net cleaning needs.

“Cooke are applying for new sites,” he explains, “and have also recently taken over two sites from Thompson Brothers – so as Cooke grow we in turn look to grow, to service their requirements".