Producer set to double smolt size

Construction of a new hatchery, which will enable Nordlaks to more than double the size of its smolts before they’re put to sea, is now well underway.

The facility will require an investment of half a billion kroner and will be located in Innhavet in Hamarøy municipality. It is due to be completed in 2019 and will employ around 20 people when finished.

While the company’s smolts currently average 100 grams when they leave freshwater the new facility will increase this to an average of 250-500 grams – both reducing their exposure to sea lice and allowing Nordlaks to achieve better fallowing of their farms.

“We have had a very good experience with fallowing several farms across a larger area. In those areas where we are [farming] alone, we have already harvested salmon without drug treatment against sea lice. With larger smolts and better coordinated fallowing we will get more of it in the future,” says the company’s environmental coordinator, Bjarne Johansen.

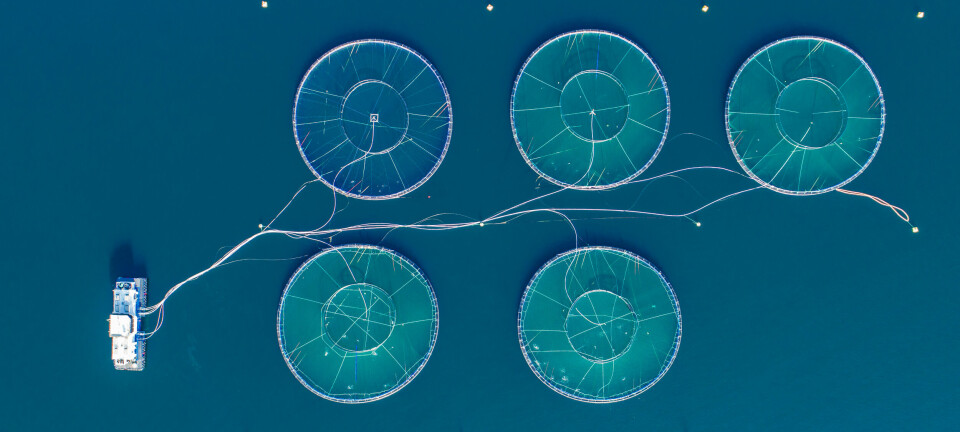

In the long term, the producer aims to stock its smolts into traditional sea cages until they reach 1kg, before moving them into their ‘Ocean Farms’ – 430m-long vessels that can be situated in exposed locations. However, the project, developed with NSK Ship Design, has yet to be granted any development concessions by Norway’s Directorate of Fisheries.

“The new hatchery will give us the big juvenile fish we need to maximize the potential of the company’s new production model. The main point is to start utilising bigger and better spaces outside fjords, especially when our next generation Ocean Farm concept – which will be tailored for this purpose – is launched,” says Eirik Welde, CEO of Smolten AS, the Nordlaks subsidiary which looks after the firm’s freshwater side of production.