Novel net washer sets up Scots base

A portable, low-cost autonomous net cleaning device is now available on the Scottish market, having met with good feedback from fish farmers in New Zealand, Canada and the USA.

Called the AutoBoss, the machine is being distributed in the UK by Stirling-based Trimara Services.

Kerry Hawthorne, Director of the company – which was established last year – tells Fish Farming Expert: “In a nutshell we are very excited to introduce this machine to the UK and Europe. With quality design and components and a new approach to net washing (‘right-sized cleaning’, ‘a little often’, ‘keeping clean nets clean’) we are providing a reliable solution and achieving consistent low-cost results.”

She has high hopes to distribute the machine in both the Scottish and Norwegian salmon markets.

“We do currently have interest from both Scottish and Norwegian companies and are looking forward to working with them in the future. Right now we have working Bosses in New Zealand, Canada and the USA, with new orders in progress. The current build time is 6 weeks and the next available manufacturing slot is late August, so we are encouraging new customers to plan ahead,” she reflects.

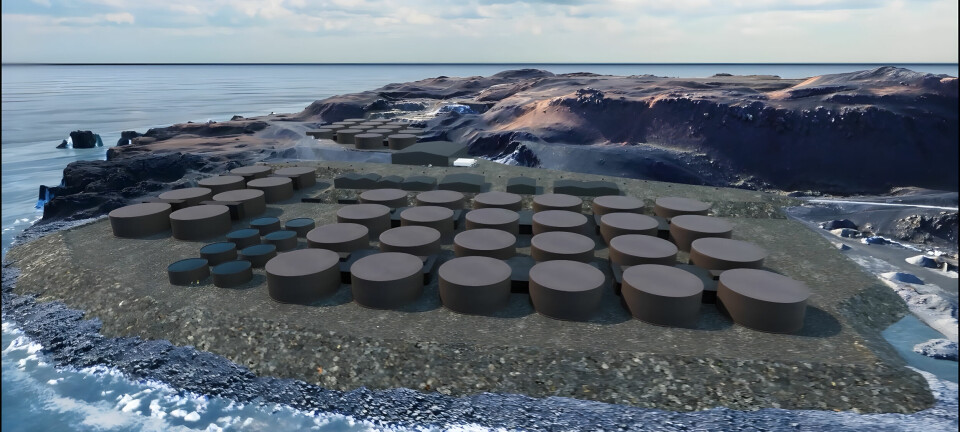

The machines are compact, weighing just 950kg, are self-contained and very portable.

“In New Zealand (where the most experienced operators currently are) she is switched from pen to pen in less than 5 minutes. This results in greater ‘up-time’ – time spent washing nets,” says Kerry.

“She is achieving a cost of 11p/m2 of cleaning,” she adds.

The device has shown itself to be fairly flexible.

“The Boss is designed to clean grower nets. She works with gravity so if there is an appropriate slope, and depending on net design, she can clean some net bottoms too. In western Canada there have been a couple of trials on predator nets which have been successful. Our manufacturer continues to look at different approaches and is also designing new products.”

Minimal manpower

She says that one of the main advantages of the system is the lack of manpower it requires.

“The AutoBoss is a programmable, autonomous net cleaning machine. Net cleaning is ripe for automation given the repetitiveness of the work, the room for human error, and the room for human boredom. The single operator’s job is to move the Boss between pens and to ensure each pen is free of encumbrances. In other words, the operator does not clean the nets, the Boss does. An on-board PLC means the operator can switch between cleaning modes – what we call ‘right-sized cleaning’ – so the operator’s job is to also assess the level of biofouling and programme the Boss accordingly. The Boss is self-contained in a pontoon; there is no external power pack. Because of her small dimensions and weight she requires just an adequate barge and crane. She is fast and can clean a 100m circle, 15 m deep, in one hour.”

Sales support

As well as selling the machines Trimara Services also offers strong sales support.

“Once an order is placed with us we visit the company’s sites and carry out a comprehensive audit in preparation for the Boss’ arrival. We look at pen set-up, nets (eg make, tautness, etc), and farm ingress/egress. We assess the environmental and geographical conditions (tides, winds, wave, fetch, etc), evaluate human resources and look at support structures. We then provide a written report to the farm managers. Once the machine arrives at the site we bring in our specially trained engineers and commission the machine. We then train the company’s mechanics and operators. Our training package includes the commissioning day, a full day in the classroom, plus 3 days on the farm working alongside the operators.

“A further 10 days of on water support is offered as part of this initial training package which is included in the price. We offer an on-going monthly analysis of performance which enhances the operator and management engagement, we continue to work with operators on pen set up and specific ‘right-size cleaning’ solutions and we establish a support network where our engineers and operators are available 24/7 for coaching users through issues,” she concludes.